World War 3D: How success on tomorrow’s battlefield will depend on the agility and flexibility provided by Additive Manufacturing

The United States Marine Corps must effectively leverage additive manufacturing or risk losing in the next war.

Recent wars in Iraq and Afghanistan enabled the Marine Corps to be supported by large built up logistical bases which utilized a hub and spoke model for the distribution of supplies and forces.[1] In 2016, General Neller, the Commandant of the Marine Corps, published the Marine Corps Operating Concept (MOC) in order to explore how the Marine Corps will operate in the 21st Century. Additive manufacturing (AM) provides a logistical capability that will help enable General Neller’s vision for how future Marine units will operate.

In the 21st Century Marines will be required to operate in smaller units and in a distributed and isolated manner due to the current and future capabilities of potential adversaries. A significant problem facing any expeditionary force is the logistical infrastructure which enables units to repair broken equipment, drones, or vehicles. The concept notes that Marine Logistics “must be capable of supporting distributed units on a widely dispersed battlefield” and that it “must be responsive, agile, and resilient to support and sustain operations on the move in austere environments and frequently on short notice.”[3] In order to limit the burden on traditional resupply lines in the described operating environment, AM would enable Marines to make timely repairs for aircraft and vehicles that are forward deployed to Expeditionary Advanced Bases (EAB) while reducing the strain on the already heavily stressed traditional supply infrastructure.[4] Mobile AM capability can help augment these traditional re-supply methods by providing more flexibility to the operating unit and limiting the need for inventories.

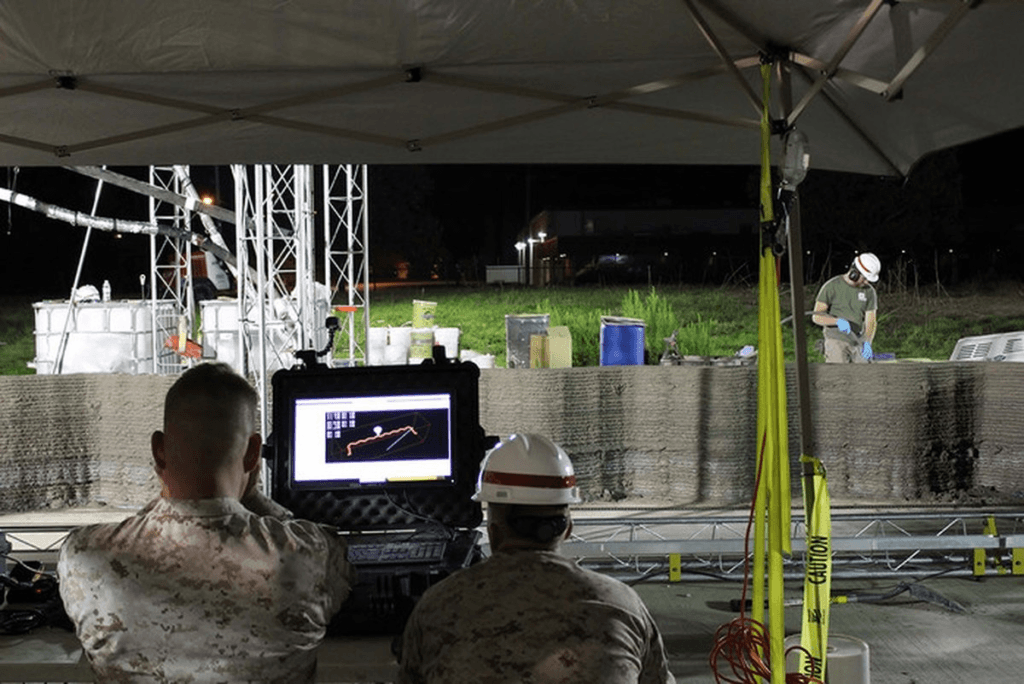

In the short term, the Marine Corps is experimenting with 3D-Printers by using them to create small replacement parts[5], by conducting experiments such as the creation of concrete bunkers[6], and by building mobile printing devices for deployed units to test[7].

[8] [9]

[8] [9]

Marines are experimenting with the new technology through pilot programs and innovation challenges. In the longer term, it is apparent that the Marine Corps is interested in finding ways to obtain the intellectual property from many of the leading defense vendors so that they can print replacement parts on their own.[10] The recent example of an aviation unit attempting to scavenge a part from an aircraft in a museum demonstrates the need for 3D printing.[11]

In order to succeed on the future battlefield, the Marine Corps must adapt current organizational structures to ensure the successful integration of AM while simultaneously working with the Federal Aviation Administration (FAA) to determine the best way to certify new parts for flight operations. One of the challenges that integrating 3-D printing brings to the Marine Corps is the need to train personnel to properly use the machines. Since the technology is still immature and improving every year, it is difficult for the Marine Corps to create a traditional qualification path. An innovative approach to manning and training that is dependent on civilian contractors for the short term is required.[12] Additionally, the Marine Corps needs to work with the FAA to create a process for 3D printed parts to be tested and certified according to appropriate safety protocols. The challenge will be integrating these safety tests into the printing process so that the parts can be immediately utilized while forward deployed. This may require additional personnel or further technology innovations for it to succeed on the battlefield of the future.

Solving the FAA certification process and required organizational changes will help set the foundation for successful integration of AM. Two major questions remain. How can the Marine Corps effectively source the required raw materials on a consistent basis? How can they stay abreast of the ever updating and improving technology? (800 words)

[1]Paul E. Williams, “Supporting SSAs in Iraq With a Hub-and-Spoke System,” Alu.army.mil, March 2006, http://www.alu.army.mil/alog/issues/marapr06/hub_and_spoke.html, accessed November 2018.

[2] “Marine Corps Operating Concept: How an Expeditionary Force Operates in the 21st Century,” Mcwl.Marines.mil, September 2016, https://www.mcwl.marines.mil/Portals/34/Images/MarineCorpsOperatingConceptSept2016.pdf accessed November 2018.

[3] Ibid., p. 23.

[4] Ibid. p. 13.

[5] Lance M. Bacon, “Here’s how Marines are using 3-D printing to make their own parts,” Marinecorpstimes.com, April 30 2016, https://www.marinecorpstimes.com/news/your-marine-corps/2016/04/30/here-s-how-marines-are-using-3-d-printing-to-make-their-own-parts/, accessed November 2018.

[6] Neil Fotre, “No sandbags needed: Marines 3D print a barracks room in 40 hours,” Marinecorpstimes.com, August 30 2018, https://www.marinecorpstimes.com/news/your-marine-corps/2018/08/30/no-sandbags-needed-marines-3d-print-a-barracks-room-in-40-hours/, accessed November 2018.

[7] John Hornick, “US Marines Mobilize 3D Printing With X-FAB,” 3dprint.com, Jan 16 2018, https://3dprint.com/200380/us-marines-3d-printing-x-fab/, accessed November 2018.

[8] Neil Fotre, “No sandbags needed: Marines 3D print a barracks room in 40 hours,” Marinecorpstimes.com, August 30 2018, https://www.marinecorpstimes.com/news/your-marine-corps/2018/08/30/no-sandbags-needed-marines-3d-print-a-barracks-room-in-40-hours/, accessed November 2018.

[9] John Hornick, “US Marines Mobilize 3D Printing With X-FAB,” 3dprint.com, Jan 16 2018, https://3dprint.com/200380/us-marines-3d-printing-x-fab/, accessed November 2018.

[10] Sydney J. Freedberg Jr., “Marines’ Love Affair With 3D Printing: Small Is Cheap, & Beautiful,” https://breakingdefense.com/2018/03/marines-love-affair-with-3d-printing-small-is-cheap-beautiful/, Breakingdefense.com, Accessed November 2018.

[11] Lance M. Bacon, “Here’s how Marines are using 3-D printing to make their own parts,” Marinecorpstimes.com, April 30 2016, https://www.marinecorpstimes.com/news/your-marine-corps/2016/04/30/here-s-how-marines-are-using-3-d-printing-to-make-their-own-parts/, accessed November 2018.

[12] Luke J. McLearen, “Additive manufacturing in the Marine Corps,” https://calhoun.nps.edu/bitstream/handle/10945/45903/15Jun_McLearen_Luke.pdf?sequence=1&isAllowed=y, Calhoun.nps.edu, accessed November 2018.

I agree that additive manufacturing (“AM”) has the potential to greatly enhance current logistical frameworks to support both combat and non-combat missions (particularly as recent transitions in battlefield tactics require the operation of smaller, more distributed and more isolated units); however, I urge extreme caution at the notion that the Marine Corps “must effectively leverage additive manufacturing or risk losing the next war.” I am also hopeful that one day, AM will revolution both our military’s capabilities as well as the costs and time horizons associated with replacement parts, but I worry about the horse getting ahead of the cart. We need to be realistic about how to pursue the use of AM and be skeptical of the technology until proven otherwise. The lives of our children are potentially at risk.

To expand a bit further, AM is still a nascent technology and, as the author notes, the Marines must be sure that any AM applications have been sufficiently tested and certified with the likes of the FAA and ISO before deploying any additively manufactured mission critical components. In reality, this day may be in the near future or the distance future (if ever) and the Marines should not assume that the it will be achieved at all. This causal job is dangerous and should not be allowed to change our psychology / outlook. I agree, that it is appropriate to engage in the experimentation of 3-D printers in field environments, but one should not assume that this will causally lead to the replacement of existing supply chain infrastructures at any point in time. That will be a future calculation based on number of inputs, including costs, environments, and the conviction that any components with be able to meet the demanding field requirements in almost any circumstances. This will require both i) significant testing in a range of environments and over time and ii) the need for quality control testing in the field for finished products to help control for and eliminate any doubt about the quality, integrity, endurance, and variability of components.

Military leaders and policy makers should push for significant R&D in AM, but be careful to alter the belief that current supply chain models will be able to be easily disintermediated or replaced – partially or fully.

Additive manufacturing has the potential to correct a significant supply chain challenge for the USMC. The fact that marines are resorting to trying to salvage parts from museum exhibits is highly concerning. As the author notes, the supply chain and distribution problem will only become more significant as marines are deployed in smaller teams and in more diverse and distant combat environments.

I would echo the concern of the first commenter here, that this technology still has a long way to go. Having some experience with 3D printing I have seen that the error rate is very high. Small changes in inputs, temperature, humidity, etc., can cause a large variation in outputs. Without the opportunity to control for these factors in the diverse combat environments our soldiers will operate in, I question how effective AM can be.

It sounds like the stakes to get additive manufacturing right are high, as it will provide the marines with enormous tactical and strategic advantages.

I am curious to understand how the military as a whole should look at ‘outsourcing’ vs. ‘insourcing’ the design of 3D printers, and how it can collaborate with the ecosystem to accelerate time to market of these technologies. Given that the military and the US government constitute a significant portion of the market opportunity, I assume that they have significant bargaining power to work with vendors and co-innovate.

This is a very interesting application of AM. I wrote about AM as well, and I think the whole industry is fascinating. In this setting, I’m particularly curious about your second question: how will the military stay abreast of new developments and updates to technology. I assume that our massive defense budget has a section carved out for future development of this technology, and I think the applications are nearly endless. I can imagine AM helping troops with more than repairs in the future. With the advent of 3D printed weapons (which I think is frightening in other settings) the military could send troops on a mission armed with their base gear, plus raw materials and a printer to allow them to adjust to changing circumstances on the fly. Need a different gun? Print it. More ammo? Print it. I understand this isn’t feasible now (see comments above about reliability), but I think it could be in the next 5-10 years. Great article!

I find this a fascinating application of 3D printing, and it makes a ton of sense. Distributed production/manufacturing (which is similar to distributed energy generation, which the Armed Forces also uses) seems like it will help increase dependability and safety of crucial parts delivery to people deployed in the field. One major issue I see is around the issue raised of obtaining intellectual property from defense contractors. I’d assume this would be a difficult feat given the fact that these companies rely on their IP as a relative advantage over their competitors. This issue made me think that we may see some new models of operation for the Armed Forces in the future – perhaps contractors embedded further within them?

This makes so much sense! I’m particularly interested that the Marine Corps is trying to get IP from defense contractors – that would save the federal government so much money and time, and help fix the government procurement process. Hopefully the government would also be able to develop more innovative capabilities in-house that could feed these new technologies.

I find this to be fascinating – the ability of AM to compress the military supply chain seems revolutionary and the author’s article is enlightening. As I read the case and think about some of the questions surrounding this technology, I would echo the concerns of some of the earlier commenters who noted that perhaps the technology has to mature and have a lower error rate to be able to be used reliably in the context of the Marines. Additionally, one concern that I might have is related to the supply chain for the inputs for 3D printers. I presume that 3D printing components are more portable and less bulky than pre-manufactured goods, but I wonder if this will still leave a small supply chain which will have to be defended at considerable cost, depending upon where the Marines are operating relative to the bulk of US and allied forces in the field.

This is certainly an interesting topic with relevant implications for the US military. However, I think it is also relevant to think about the potential implications for other militaries and perhaps more importantly, militant groups that are not as well organized. It appears that additive manufacturing could level the playing field for these groups against more organized, established militaries. Currently the US military benefits from a really strong logistical and supply network, whereas the ability of less organized groups to print weapons themselves can provide them a better opportunity to be competitive, overcoming their current weaknesses. When less organized militant groups can manufacture their own weapons, built from open source directions available online, instead of going through the complex challenges to source them in other ways, they are better positioned to be competitive in the battlefield.

I had similar concerns with the structural integrity of AM parts in crucial parts of airplanes which may be load bearing. One area of the military which is resource strapped and may not require such load bearing necessity is in medical supplies in field trauma hospitals. Hard splints, props, and surgical tools could be supported by AM parts. I know there is also research into fabric-based automated additive manufacturing, which I think would also be very helpful for supplying bandages, wraps, and other medical and military resources.

The logistics chain required to support military operations is a critical component to failure or success on the battlefield. Of all the United States Military services, the Marine Corps is considered the most expeditionary and often operates in some of the most austere environments. As a unit, it’s supply chain is generally more short term in nature than a larger more occupational force such as the U.S. Army. With this in mind, Additive manufacturing has the potential to provide a huge improvement to Marine Corps supply chain efforts. In this manner, Marines could station a 3-D additive manufacturing machine at Forward Operating Bases (FOBs) to provide supply chain augmentation. Rather that fly-in (helicopter, C-130) parts, they can use additive manufacturing to fabricate these parts.

The push to receive FAA certification is a long road and I believe the Marine Corps will find more success in the interim by focusing on using additive manufacturing to fabricate emergency parts at forward deployed locations. Examples of this include rifle components, barricades, and vehicle repairs.

Interesting and well-formulated. I particularly like the discussion of the supply chain in a constrained context. Yes, Additive Manufacturing enables simpler supply chains and faster assemblies, but you consider two important points: 1) AM can eliminate supply chains as repairs to broken parts can be done using AM, and 2) there may still need to be a supply chain in order for raw materials to be shipped to the consumer, thereby eliminating the supply chain advantage. The best solution to #2, to me, is to use existing materials on Marine Corps uniforms / trucks or raw materials from combat zones, as the raw materials in a 3D print.

I did not know this was happening and it sounds amazing. A big challenge here is protection on cyber attacks that could steal the detailed information on weapon construction. If this information falls in the wrong hands, the enemy could be matching up the military’s arsenal in a specific battle. Also it will disclose how many weapons and what type of provisions the military is bringing to the field. Another risk with cyber attacks could come from hackers changing the amount of weapons built or even the quality that will be produced.

This is such an interesting application of 3D printing! Innovating in this area has the potential of significantly giving the US a leg up in terms of military technology. I wonder if other countries are beginning to think about this as well. I would assume Russia and many European countries would be thinking about matching these capabilities the moment they found out about this. Of course, this requires significant capital investments.

I do think the point on the changes in talent acquisition and training that this implies is extremely important. Apart from having to train engineers to be able to operate these machines, they will also have to build up their legal teams as they begin to obtain the intellectual property of this equipment. Likewise, as the military adopts a larger role in producing materials as opposed to sourcing it from third parties, they will need to begin hiring experts in manufacturing. As the application of this technology is broadened it will be interesting to see a shift in profiles of people entering the military.

This was particularly interesting article and it has certainly piqued my interest. I would be curious to see if / how the Marines are able to get the IP from defense companies. If they do, how will defense companies be compensated and how will that be tracked? Will it save money or be even more costly? In addition, this can be concerning as a lot of these parts could be highly classified and the IP must be closely safeguarded. With added convenience, there is the trade-off of safety. Will it be harder to safeguard these closely held secrets if the specs are much closer to the front line? If lost, is the government to blame? How will defense companies react? I think this overall initiative makes total sense, but there are a lot of unanswered questions. I am curious to see where this ultimately ends up.

Very interesting and important. I’ll be very curious to understand how the government and policies adjust to the new normal where original equipment manufacturers (OEMs) have such a monopoly of the understanding of the manufacturing of goods critical to government operations, particularly in the military. This seems like a change of power that will have cascading effects.