Will additive manufacturing make space more accessible than ever before?

Imagine a world where any company can cost-effectively launch a satellite into orbit. With Rocket Labs latest innovation in 3D printed rocket engines, this reality is closer than you think. But can Rocket Labs remain competitive in an increasingly crowded space industry?

A New Era of Satellites

It was only 61 years ago that the first satellite, Sputnik, was launched by the Soviet Union [1]. Today, there are over 4,800 satellites in orbit [2]. Much of this growth can be attributed to the increasingly attractive launch of smaller, lightweight satellites into low earth orbit (LEO) [3]. The LEO orbit is the closest band to earth (120-1200 miles) and is one sought after by technology companies for its data applications and lower latency levels [4]. In 2017, 292 of these smaller satellites were launched, up from just 55 in 2016 [5]. Furthermore, we are seeing a shift from the public sector to more commercial satellite launches (Figure A) [6].

Figure A

What has made this possible?

Advances in technology have allowed smaller satellites to perform the same tasks as their predecessors at lower orbital levels [7]. Additionally, we are seeing an emergence of new commercial launch providers working to reduce the cost of the rockets used to launch these satellites. One of these companies is Rocket Labs, who built a first of its kind rocket engine composed entirely of 3D printed parts [8].

The Benefits of 3D Printing

Additive manufacturing, often called 3D printing, “is a process used to create a three-dimensional object based on a digital file.” [9]. Unlike traditional manufacturing, parts are built by adding materials one layer at a time based on an easy to update digital design. In the case of the aerospace industry, this allows for the creation of lighter weight, more fuel efficient engines that can carry heavier payloads into space [10]. This has resulted in a host of new startups emerging to try to capture the expected increase in commercial satellite launch demand.

Rocket Labs Revolutionary Approach

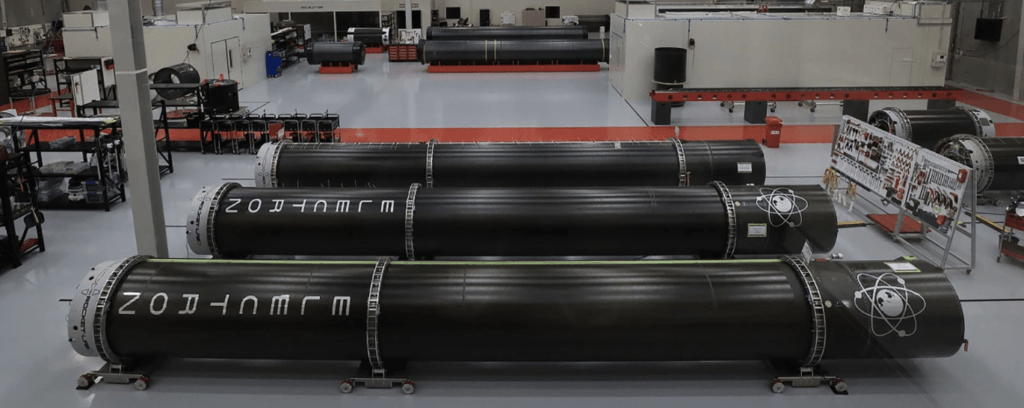

Rocket Labs, a US Aerospace Company, was founded in 2006 by Peter Beck with the mission of “opening access to space to improve life on Earth … by developing and launching advanced rocket technology to provide rapid and repeatable access to orbit for small satellites” [11]. Rocket Labs has differentiated itself by building the first ever rocket engine manufactured entirely by 3D printing (Figure B). The use of additive manufacturing is a critical factor to their success as it allows for “unprecedented launch frequency” by reducing the engine build time from months to just 24 hours [9]. This will allow them to launch more payloads per year and rapidly scale their customer base. They also significantly reduced the cost per rocket, down to just $5M, allowing them to charge customers less per payload.

Ensuring Long-Term Sustainable Growth

Rocket Labs is not the only company vying to be the provider of choice for companies looking to launch small satellites. There are over 100 startups, including Richard Branson’s Virgin Orbit, looking to tackle this problem. Most of these companies, however, will fail due to a lack of proven technology or insufficient capital. How can Rocket Labs ensure long-term success?

On November 10, 2018, Rocket Labs successfully launched their first payload into space. While this is a major achievement, it is important that they do not become complacent. The 3D printed engines are a new technology and not enough time has passed to fully understand the effects of space on the materials. It is important that Rocket Labs continue to invest in R&D to improve the strength and durability of the lightweight engines. The company that ultimately provides the lowest cost launch solution to customers will succeed.

It would also be wise for Rocket Labs to continue to vertically integrate their manufacturing and launch processes at both their US and New Zealand launch facilities to further reduce costs. Finally, major defense companies are beginning to buy into these small startups rather than invest in their own in-house capabilities [7]. Rocket Labs must showcase its technology to these defense companies in order to lock in potential long-term contracts.

Questions for the Future

- As it becomes easier to launch satellites into LEO there will undoubtedly come a time where further regulation is called upon due to privacy and defense concerns as well as a crowded orbital space. How can Rocket Labs ensure that it gets ahead of any policy changes that could limit their future business potential?

- Additionally, Rocket Labs has a chance to move their business beyond just carrying consumer payloads to space towards eventually carrying humans to space. How would this change the degree of testing required on their 3D engines, for surely human lives will require a much higher degree of confidence in their technology?

(799 words)

Sources

[1] Steve Garber, “Sputnik and The Dawn of the Space Age”, Nasa, October 10, 2007, https://history.nasa.gov/sputnik/

[2] Pixalytics, “How many satellites are orbiting the Earth in 2018?”, https://www.pixalytics.com/sats-orbiting-the-earth-2018/, accessed November 11.

[3] “The New ISPs In the Sky,” Trends Magazine. Aug 2017, Issue 172, p37-42. 6p.

[4] Stewart Sanders, “The new space race is all about satellites: Pros and cons of each orbit” The Next Web, November 3, 2018, https://thenextweb.com/contributors/2018/11/03/the-new-space-race-is-all-about-satellites-pros-and-cons-of-each-orbit/

[5] Aaron Gregg, “Defense giants bet big on small satellites” Washington Post, September 16, 2018, https://www.washingtonpost.com/business/2018/09/16/defense-giants-bet-big-small-satellites/?noredirect=on&utm_term=.e69118e32f6f, accessed November 11.

[6] “A Big Bet on Small Satellites,” MIT Technology Review. May/Jun2017, Vol. 120 Issue 3, p27-27. 1p. 1 Graph, 1 Map.

[7] Kenneth Chang, “Rocket Lab’s Modest Launch Is Giant Leap for Small Rocket Business,” The New York Times, November 10, 2018, https://www.nytimes.com/2018/11/10/science/rocket-lab-launch.html, accessed November 11.

[8] Michael Petch, “INTERVIEW: ROCKET LAB REACHES ORBIT FOR FIRST TIME, ANNOUNCES NEW ADVANCE FOR 3D PRINTING POWERED MISSION,” 3D Printing Industry, January 23, 2018, https://3dprintingindustry.com/news/interview-rocket-lab-reaches-orbit-first-time-announces-new-advance-3d-printing-powered-mission-127880/, accessed November 11.

[9] Spaeth. 3D printing is changing the face of multiple industries. ECN: Electronic Component News 61, no. 9 (October 2017): 21–23.

[10] W.J. Lim, K.Q. Le, Q. Lu, and C.H. Wong. An overview of 3-d printing in manufacturing, aerospace, and automotive industries Links. IEEE Potentials 35, no. 4 (2016): 18–22.

[11] Rocket Labs, “What We Do”, https://www.rocketlabusa.com/about-us/, accessed November 11.

The recent trend of commercial satellite launches taking over for the public sector is both fascinating and exciting. The fact that Rocket Labs is using 3D printing to create its engines was surprising as I didn’t realize the technology was mature enough. Decreasing the build time from months to 24 hours is especially impressive and obviously represents a key advantage for the company. One of the challenges I see facing the company is how they can create technology or a process to effectively inspect and test the engines to a safety standard. While the FAA may not be entirely prepared for the space industry Rocket Labs can get ahead of the competition by creating their own process for quality control and inspection. From my limited understanding of 3D printing, quality can vary widely with the current technology. I agree with the author that locking in long-term defense contracts is essential for success. Having an ally like the military will make weathering future policy changes easier.

This is an interesting look at the potential future of space commercialization. I wonder about 2 areas for future development. One is the future of the materials. Does the introduction of 3D printing allow for the use of new, more innovative materials that might be lighter or more heat resistant and could then be printed into rocket parts, beyond just the engine? And the second is how the public sector will play a part in the development in space. Given it is not just a US issue, how will international bodies react in the coming years to the quick ramp in satellite traffic?

This was very interesting to read. While it is very fascinating to know how AM is playing a role in shaping the future of space commercialization, I would question the role of governments and global relationships in helping advance this work. Rocketlabs seems to be a fairly new company (2006) as per your article, but the fact that they can already claim to reduce the manufacturing time significantly is a ray of hope for all of us. (“unprecedented launch frequency” by reducing the engine build time from months to just 24 hours). This might bring a giant leap for mankind again!