The Onslaught of Digital unto Nuclear Dinosaurs

Digital technology represents a serious of very specific challenges to the nuclear industry based on its regulatory structure and current market pressures.

The phrase “nuclear power” typically conjures images in the mind of the reader of space age technology controlling a very precise source of power. Reality is quite far from perception in this case; as the Nuclear Energy Institute states “nearly all operating U.S. reactors that were built in the 1970s and 1980s have analog instruments from that period”[1]. Indeed, walking into a nuclear plant control room for the first time feels like stepping into a time machine and coming out the other end.

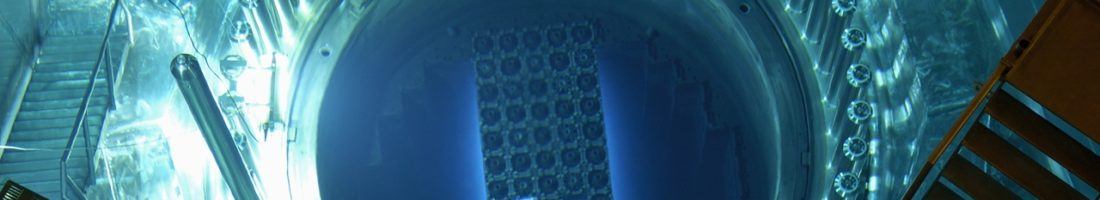

Source: Oak Ridge National Laboratory

The mere mention of digital upgrades induces cringes on any of a nuclear plant’s managers, particularly engineering and financial managers. To understand why this happens, one must understand how nuclear plants are regulated and operated, and why they are operated as such.

Nuclear plants are operated on the principle of maintaining “design basis”. Each nuclear plant has a Safety Analysis Report, typically around 2,000 pages, that describes how each part of the nuclear plant has been designed to withstand all the worst-case accidents postulated. Each page of this report contains only the conclusions of the calculations and analysis; therefore, behind every page there are thousands of pages of calculations and documentation supporting those conclusions. It is no wonder then that changes to the plant configuration are attempted to be minimized; with so many documents and analyses to update and take into account every time a change is made, the engineering costs associated with even minor changes are much larger than in any comparable industry. On top of this issue, the antiquated IT systems[2] at most nuclear plants make retrieving all the relevant information very difficult, making it very likely that something can be missed when a design change is of large scope and complexity.

In an ideal world for nuclear managers, they would not have to change anything, and they could keep replacing their analog controls every 10 years. There is some merit to this philosophy, as the reliability of purely analog circuits is actually quite high. The market conditions of today, however, require a different approach to be taken. Obsolescence becomes a bigger problem every year at these plants, as their spare inventory is depleted and no like for like replacements are available. Additionally, the competitive environment in many regions of the US brought about by inexpensive natural gas and wind power has brought immense pressure on nuclear plants to find ways to innovate, operate more efficiently and cut costs. These pressures have already brought an unprecedented number of nuclear plants to announce closures over the past year[3][4]. In an environment of accelerating climate change, this is cause for concern as every nuclear plant closure takes offline 800-2000 MW of CO2 free power.

How can the nuclear industry embrace digital change? A few initiatives could make big improvements for nuclear plants:

-Improvements in operational IT systems – This is an area that is not regulated, and has really lagged behind similar industries because of the spillover from the anti-digital mindset in the regulated plant modifications. In particular, plants should invest in indexing of all their current information to ensure it is machine searchable. This will position utilities more advantageously as the advancements in machine learning allow the industry to automate a large portion of the current administrative work that high cost engineers are currently performing.

-Standardize design change process across industry – The nuclear industry is very particular in that it realizes that the threat each plant faces apply to the industry as a whole, and that the safety and operational efficiencies that come from collaborating are much larger than the advantages from withholding information and competing. Contributing to this is the fact that nuclear plants usually service specific geographic areas and rarely compete with each other bidding for the same market. This advantage can be leveraged to also reduce the cost of performing digital upgrades by standardizing the evaluations performed for each change. Currently, plants perform analyses on a very specific basis for each plant’s process and configurations, even though plants are very similar in design and operation.

-Stronger use of data analytics to enhance and automate scheduling operations – Work scheduling at nuclear plants is a very touch heavy operation[5], and as a consequence, many inefficiencies and errors occur which result in low utilization of workers due to the large number of factors that have to be considered when making a scheduling decision.

Understanding the environment and the market, the nuclear industry must look to digital as a tool to achieve operational efficiencies and as truly the only way to survive going forward.

Word count: 761

Bibliography

[1]http://www.nei.org/News-Media/News/News-Archives/Digital-The-New-Word-in-Nuclear-Power-Plant-Contro

[4]https://www.ferc.gov/industries/electric/indus-act/rto/energy-price-formation.asp

Thanks for the great analysis, Jaime! While there would certainly be operational efficiency improvements if the nuclear power industry utilized more digital technology, this would also bring significant security risks into the picture. Nuclear power plants are strategic national assets that international adversaries and non-state actors seek to exploit. The industry’s hyper-focus on safety and physical security often overlooks the growing threat from cyber attacks. A 2015 report from Chatham House detailed 50 recent cyber attacks on international nuclear power infrastructure and determined there is a “culture of denial” in the nuclear industry about the cyber threat (1). Critical nuclear power plant components and cooling systems can be compromised via cyber attack, and increasing the use of digital technology would widen these risks.

(1): https://www.ft.com/content/b5f0df54-6aa1-11e5-aca9-d87542bf8673

Interesting read, Jaime. The energy industry as a whole is certainly guilty of relying on obsolete technologies and waiting far too long to upgrade. Look at the fact that many utilities still have manual meter readers driving around to check customers’ monthly energy usage. Given the fact that many operators have been so loathe to update their analog operating systems, has there been any development in digital systems to support nuclear reactors? If so, who is developing and who are the customers who are using these technologies? I don’t know if this would be a potential usage of something like GE’s Predix software, which could likely be customized for the reactor. Any idea on how the new TVA nuclear plant, or the ones being built in Southern Company Territory will incorporate digital monitoring and analytics in these new nukes? I’d think that the ability to generate and analyze data would be a benefit to the permitting process on new plants, but given how long these took to permit and built, I’m not sure if this was the case.