Paper for the Planet

WestRock is a paper and packaging company that, despite its reliance on the cutting down of trees, has undertaken multiple notable steps towards increased sustainability.

(800 words)

How much pizza is too much pizza? Some of you might say ‘not possible. But, if you are like me, you were over pizza by the second week of the semester. How would you feel, if you knew that the hundreds of boxes of pizza we collectively accumulate each week actually contribute to preserving our ecosystem? What if you were saving the planet, one slice of pizza at a time?

From pizza boxes to medical pill packets to packs of cigarettes (unfortunately), WestRock charges ahead to innovate in papermaking and packaging. As unsexy as the industry may be, paper and cardboard are integral to so many of our daily activities. WestRock services millions of people with its products every day. As a company that produces over 13 million tons of paperboard and billions of boxes, cartons, dispensers and displays annually[2], WestRock can, and does, have an immense impact on how we humans engage with the planet.

To provide some background, WestRock was recently formed in 2015 following the merger of MeadWestvaco Corporation and Rock-Tenn Company, and it is the second-largest American packaging plant after International Paper Company for corrugated containerboard[3]. The CEO, Steve Voorhees, and Chief Sustainability Officer Nina Butler supervise WestRock’s upholding of its purported values: integrity, respect, accountability, and excellence.

Recyclable paperboard for the PerfPak Advantage medication cards

By virtue of its business depending on cutting down trees, WestRock is greatly impacted by climate change. First off, it is inherently under heightened scrutiny as a contributor to the ever rising CO2 emissions that remain in the atmosphere instead of quite literally being anchored into the ground[4]. This increased carbon (energy) trapping in the atmosphere contributes to climate change by overwarming the earth, which we experience as rising coastlines, shrinking glaciers, and spring weather in November. WestRock acknowledges this fact and flips what could be an extremely negative role into an opportunity to champion sustainability and conservation of forests and the surrounding ecosystem.

To frame its sustainability goals, WestRock established its 3Ps: People, Planet, Performance. Specifically, the company takes on on local and global ecological challenges, from preserving Golden-winged warbler habitats in Virginia to sponsoring schoolchildren’s education about the ramifications of deforestation and environmental pollution in Brazil through Project Learning Tree [5].

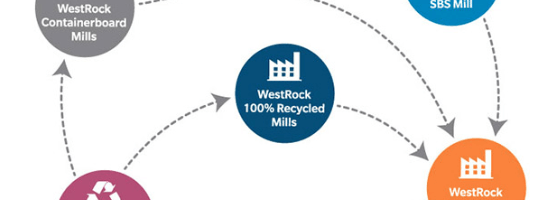

Moreover, WestRock has a robust recycling business. Yes, it produces 13 million tons of paperboard, but it also recovers and recycles 7 million tons of wood fiber in its own recycling facilities and paper mills. If you buy any product packaged by WestRock, they will come pick it up from you – an individual customer or a larger corporation – and pay you for the recyclables! That is a pretty great incentive to treat the planet right [6].

This recovery of recyclables actually goes even further to save businesses money by freeing up more space in their dumpsters for them to dispose of other materials. Instead of dumping waste into landfills to decompose into methane emissions, companies can now turn their waste into raw material to combine with virgin wood fiber and transform into the quality packaging we see every day. WestRock talks the talk and walks the walk, using its sustainability initiatives to reduce its carbon footprint[6].

In addition to its recycling initiatives, WestRock tries to keep its suppliers honest. After a rigorous supplier approval process, the company holds its suppliers to its WestRock Principles of Conduct that require compliance with laws, legal requirements and regulations regarding virgin wood fiber or recycled fiber acquisition in 11 U.S. fiber procurement regions. The company also has two Independently Managed Group certificates through the American Tree Farm System that gives it greater control over the activities of >250 landowners and >230,000 acres of land[7].

To keep itself honest, it routinely runs its own chemical and microbiological testing, and abides by multiple certification requirements, including the Sustainable Forestry Initiative and the Forest Stewardship Council. It also employs a large independent auditing system to ensure that the company strives to protect forest ecosystems and complies with established laws.

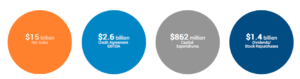

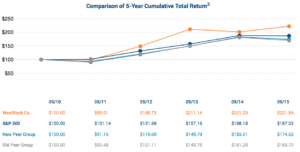

In light of all these great initiatives, one might ask, “Well, how is WestRock really doing?” The numbers speak for themselves.[8]

Sales are booming.

Stock prices are trending up.

The 5-year cumulative total returns fly above the market.

What is next for this company? It has covered sustainable forestry, mixing virgin wood fiber with recycled fiber, and creating a robust recycling program. To increase its impact, it should partner with companies that are struggling to achieve their sustainability goals in order to compound its positive benefits on the industry. Additionally, continual reduction of the amount of paper or cardboard required for individual packaging and the possibilities of reducing that with bulk shipments will incrementally improve the good work it already does.

Hopefully, we can all feel a little less guilty when ordering pizza now.

[1] Tita, Bob. “Super Bowl Challenge for Box Makers: 12.5 Million Pizzas.” Wall Street Journal. January 29, 2015. http://www.wsj.com/articles/packaging-companies-meadwestvaco-rocktenn-to-merge-1422272094

[2] WestRock. (2016). https://www.westrock.com/en/company

[3] Tita, Bob. “MeadWestvaco, Rock-Tenn to Combine.” Wall Street Journal. January 26, 2015. http://www.wsj.com/articles/packaging-companies-meadwestvaco-rocktenn-to-merge-1422272094

[4] Henderson et al. “Climate Change in 2016: Implications for Business.” Harvard Business School. October 14, 2016.

[5] WestRock. (2016). https://www.westrock.com/en/sustainability

[6] WestRock. (2016). https://www.westrock.com/en/sustainability

[7] WestRock. (2016). https://www.westrock.com/en/forest-resources

[8] WestRock. (2016). http://ir.westrock.com/phoenix.zhtml?c=254016&p=irol-irhome

Really interesting article and sounds like WestRock is taking many steps to reduce their environmental impact. I wonder if they can partner with their clients to together think about how to create more sustainable packaging options, both in terms of materials used, but also packaging design. For example, Poland Spring redesigned their water bottle in 2012 and was able to achieve both supply chain savings and decrease plastic and energy used in each water bottle (http://www.slate.com/articles/business/operations/2012/06/poland_spring_s_new_bottles_why_are_they_so_thin_and_flimsy_.html) I wonder if WestRock could really build out the capacity and expertise to help their clients think more strategically about their packaging and help them achieve cost savings and have a positive impact for the environment.

Very nice post! WestRock clearly has a good handle on sustainability despite being such a huge producer of paper products. I’m curious if there are any innovations that we will see in the future related to paper production. Does it HAVE to come from trees? Is there a production process like particle board that uses a higher % of the logs cut down?

A common trend I’m seeing here with companies that truly tackle sustainability is that they address sustainability at all levels of the supply chain. From their own manufacturing, to ensuring compliance from wood procurement, to recycling over half of their own production, WestRock has clearly made a strong commitment to reducing it’s minimizing it’s ecological impact and I wholeheartedly believe that this is related to its continued success. Good work!

Thanks for the interesting article, NAK. But also sorry to hear that you are sick of pizza because I don’t think it’s going anywhere for the next three semesters of your business school career. 🙂

I would like to learn more about how WestRock’s recycling program works, and the logistics of how they are able to pick up recycled packaging from customers. I wonder what type of transportation costs and subsequent energy consumption and CO2 emissions come into play from this system. I also wonder how this recycling program is marketed to customers to make them aware of it. My understanding is that WestRock creates packaging for its clients, and therefore would not have a strong brand presence in the minds of consumers.

Regardless, I think the initiatives that WestRock is taking to make the paper and packaging industry more sustainable are commendable. I think it’s important for companies to look into how sustainability practices (such as WestRock’s recycling practices) can save a business money. That way, incentives of the company and prevention of global climate change are aligned. I also think it’s great that WestRock has an internal auditing process to make sure that standards are being followed.

I would challenge that their business has to depend on cutting down trees. Its admirable that they already achieve 54% post-consumer inputs by leveraging recycling, but they are positioned to push that to 100% before their competitors due. This could eliminate their reliance on forests, and improve their bottom line even further.

Having worked for Amazon, I constantly challenged the need for cardboard boxes given the wastefulness of using them one time. The only positive benefit of cardboard is that it is so highly recyclable (when not covered in pizza grease) and fairly renewable even when deforestation is necessary. And the truth is that most alternatives can be worse than the cardboard incumbent solutions. For example, reusable containers often require 100x the usage to justify the additional upfront investment in manufacturing, for example a plastic alternative such as a tote. The same could said for pizza, for example, if Domino’s started delivering in reusable pizza boxes how many would get trashed before crossing the breakeven point in carbon footprint. One thing WestRock could do is to continually monitor the alternatives and even invest in ones they think are able to disrupt the use of paper goods. Eventually someone will come up with a better solution than just a box, so better if WestRock odes it first.