GE’s Industrial Internet of Things

With their imagination at work, GE is at the cutting edge of innovation and their investments in digital and analytics are testament to the relevance of these technologies to businesses of all types moving forward.

INDUSTRIAL DIGITIZATION

In today’s world, managers, even in sectors that many of us may not attribute with high-tech, are thinking about their businesses differently. General Electric (GE), like many other businesses, has recognize the importance of digitization and how it relates to their quickly evolving industries. As GE CEO Jeff Immelt noted, “If you went to bed last night as an industrial company, you’re going to wake up this morning as a software and analytics company.” [i]

GE DIGITAL

Over the course of the last several years, GE, like many other industrial companies, began to invest heavily in what is called the Industrial Internet of Things (IIoT), leveraging technology and big data to improve operational efficiencies, productivity and uptime. In 2015, GE Ventures (GE’s venture capital arm) invested in software company ServiceMax as part of a $82 million Series F funding.[ii] Later that year, GE bolstered its position on the IIoT by forming a new division, GE Digital, with the mission to grow its $6 billion software and data analytics enterprise to a top 10 software company by 2020.[iii] Since then, GE has used this enterprise to build a cloud based platform as a service (PaaS), Predix, fostering innovations in technology across business units from GE Power to GE Oil & Gas to GE Aviation. In 2016, GE Digital strengthened its commitment to the IIoT by purchasing ServiceMax for $915 million to realize synergies and accelerate the implementation of their Predix platform.[iv]

Photo courtesy of https://techcrunch.com/2016/11/14/ge-digital-snags-servicemax-for-915-million/

PREDIX, POWERUP & GE WIND

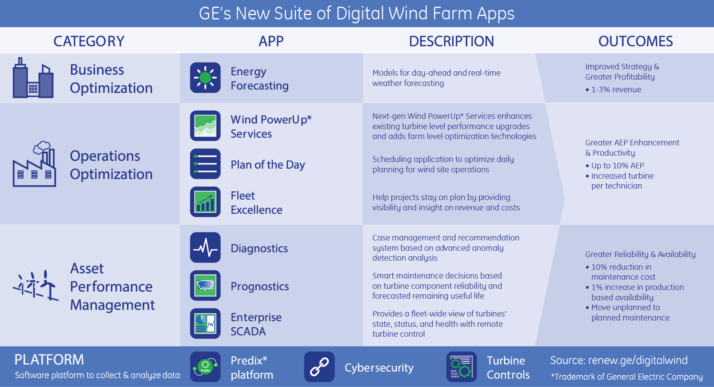

GE has bet big on their Predix platform and it seems to be fostering a win-win for both GE and their customers – especially in wind. Equipping their best in class wind turbine technology with computing power and an army of sensors, GE is able to harness real time data on nearly every aspect of the asset and resource conditions to drive intelligent operational and maintenance decisions. Sensors collect data from each individual turbine such as weather conditions (e.g. wind, rain, humidity, etc.), operating metrics (e.g. blade pitch, turbine yaw, etc.) and the corresponding performance metrics (e.g. generator output, temperature, vibration, etc.). The Predix platform synthesizes data collected, applies predictive analytics and ultimately actionable insights to the operations & maintenance team. Wind farm O&M teams can forecast operation plans and yield improved operational efficiency by adjusting turbine parameters based on performance trends. The same data can be used to optimally schedule for planned maintenance during low-resource hours. In addition, Predix can compare unit-unit performance, point out performance trends and anomalies and thereby allow for proactive service decisions that can reduce downtime and increase overall efficiency. Furthermore, through a software and controls hardware add-on PowerUp, GE is able to harness the Predix analytics to make real-time performance adjustments to the turbine to continuously enhance power output as external conditions change. With these benefits in mind, GE claims that the platform can improve a wind farm’s lifetime energy output by up to 20%.[v]

Photo courtesy of http://www.politico.eu/sponsored-content/disrupt-or-be-disrupted/

WIND

During a time where government subsidies in the U.S. for wind will soon sieze, companies like GE rely on innovation to improve the performance of their products to reduce the levelized cost of wind energy and ensure the long term sustainability of this business division. Through the Predix and PowerUp platforms it appears that GE has made strides in improving the efficiency of their technology, increasing the ROI for their customers and thereby strengthening their position in the market.

Photo Courtesty of https://www.gerenewableenergy.com/wind-energy/

THE FUTURE

Moving forward, I envision GE as the global leader in IIoT software technology. I would like to see them extend their approach of the IIoT into manufacturing by integrating the Predix platform with the equipment offerings of companies like Mazak, Haas, Okuma, Panasonic. By enabling machine learning, GE can influence production efficiencies of their manufacturing suppliers, thereby reducing costs, and capturing more market value.

Could data analytics stimulate a revolution in productivity and efficiency? Could this be the key to renewable energy? Could the same analytics drive massive improvements in manufacturing processes? These are questions that industrial giants like GE, and business leaders like Jeff Immelt are forced to consider when planning for the future.

Photo courtesy of https://www.gepower.com/

[700 words]

Works Cited:

[i] Recharge News. 2015. Big Data giving wind the right numbers. [ONLINE]. http://www.rechargenews.com/wind/1034134/big-data-giving-wind-the-right-numbers. [Accessed 15 November 2016].

[ii] Tech Crunch – Ron Miller. 2016. GE Digital snags ServiceMax for 915 million. [ONLINE]. https://techcrunch.com/2016/11/14/ge-digital-snags-servicemax-for-915-million/. [Accessed 15 November 2016].

[iii] Bloomberg – Rick Clough. 2015. GE Forms Digital Unit to Expand $6 Billion Software Business. [ONLINE]

https://www.bloomberg.com/news/articles/2015-09-14/ge-forms-digital-unit-to-expand-6-billion-software-business. [Accessed 15 November 2016]

[iv] Bloomberg – Rick Clough. 2016. GE Deepens Silicon Valley Push With $915 Million Cloud Deal. [ONLINE]

http://www.bloomberg.com/news/articles/2016-11-14/ge-deepens-silicon-valley-push-with-915-million-cloud-purchase. [Accessed 15 November 2016]

[v] GE Renewable Energy. 2016. Digital Wind Farm Brochure_R3. [ONLINE] https://www.gerenewableenergy.com/content/dam/gepower-renewables/global/en_US/documents/product-brochures/ [Accessed 15 November 2016]

Interesting read. Smart censors and big-data analytics capabilities provide a compelling new way for companies to boost equipment efficiency. This is especially true for alternative energy sources – which run way below capacity. Zooming-in on wind turbines, they only generate around 24% of their total capacity. Of course, the main reason for this is variability in wind patterns, but any efficiency improvement translates into major gains in terms of relative output (a 1 percentage point increase is a 4.2% gain if your base is 24%)

However, IIoT efficiency improvements are still capped at the capacity of the underlying equipment. For manufacturers already running at almost full capacity, it seems like IIoT’s main value-add will be in optimizing maintenance in order to eliminate costly equipment failures.

Very interesting post. I have some experience with GE’s investment in digital infrastructure through the Digital Manufacturing Design and Innovation Institute (DMDII – http://dmdii.uilabs.org/). GE is essentially leading a consortium of academics and industry leaders to research and develop state of the art advanced manufacturing technology, similar to the tech. you’ve described here. One major concern that these organizations have is cybersecurity. For example, if my large industrial machines (e.g., wind turbine) are now connected to the internet, that makes them incredibly vulnerable to cyber attacks, which could have seriously expensive / harmful consequences. As GE advances its digital organization, Predix, etc., I hope they will also take a leadership role in defining the cybersecurity standards and requirements necessary to facilitate the “Industrial Internet of Things”.