Digitization at Intel – the company that ‘created digital’

Intel, the world's semiconductors pioneer, is leveraging digital supply chains to optimize its manufacturing.

Background

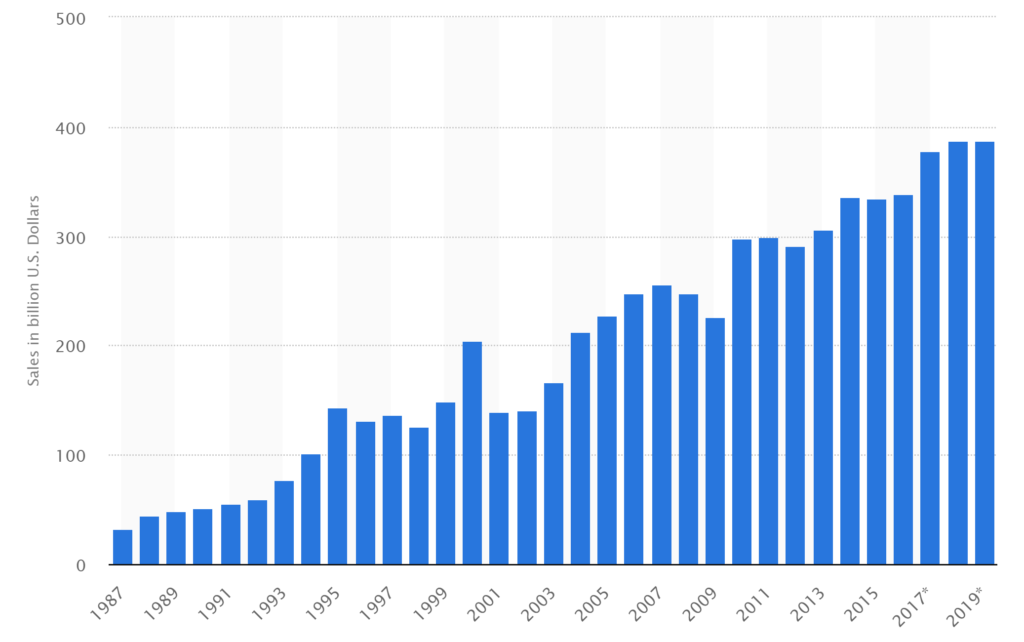

Semiconductors are the ‘brains’ that power computers, smartphones, and tablets.1 To fuel our digital revolution, the size of this industry naturally exploded. Exhibit 1 shows that global semiconductor sales revenue grew tenfold from USD ~33 Bn in 1987 to USD ~338 Bn in 2016.2 As the industry matured, revenues got consolidated and captured by key global players; Intel pioneered the industry, and captured ~16% of the global market share in 2016.3

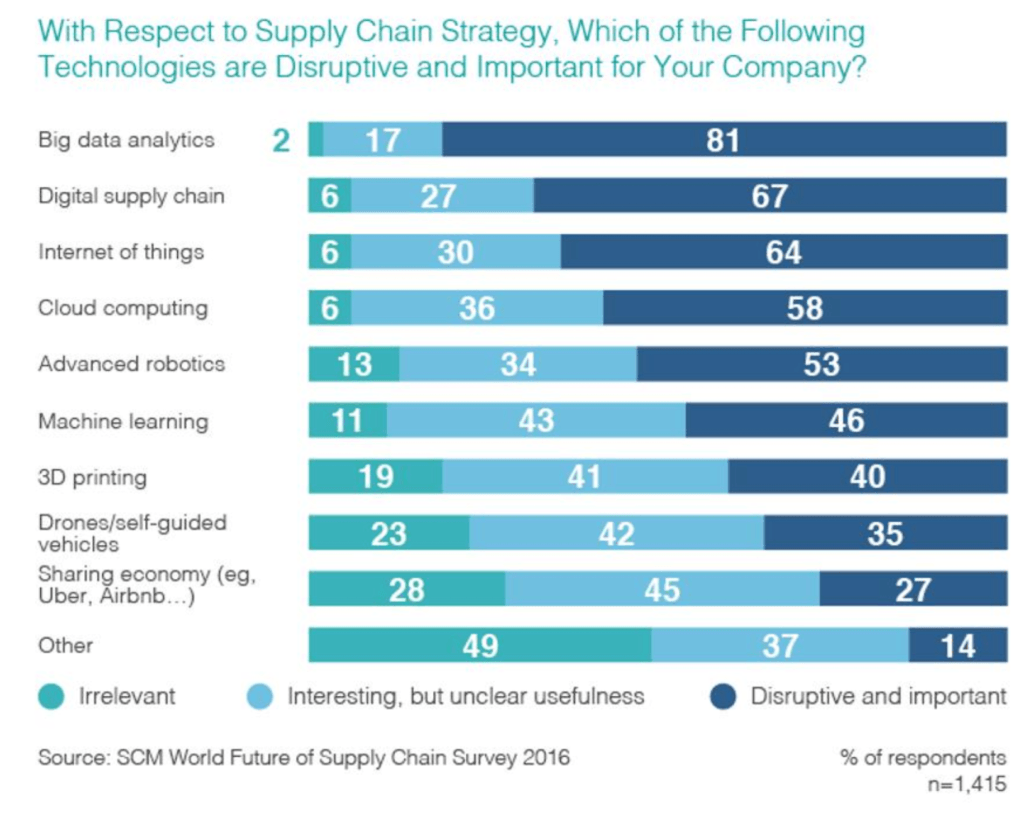

In line with most manufacturing companies, supply chain optimization played a major role in reinforcing semiconductors companies’ competitive advantage. Digital solutions then emerged to help optimize supply chains, and a recent study shows that more than 67% of CEOs consider digital supply chains to be ‘disruptive and important’ as shown in Exhibit 2.4

Relevance for Intel

Intel’s profitability is directly linked to the efficiency of its supply chain for a multitude of reasons. Firstly, the semiconductor industry has been plagued by constantly decreasing margins, putting more pressure on manufacturers such as Intel to significantly scale up their operations to remain profitable. In fact, Intel “fulfills over 1 million orders a year from several factories across 100 countries.”5,6

Secondly, the business includes huge variability in customer demand coupled with a large number of suppliers. In fact, “the average order is changed 6 times and only 1% of orders are shipped without any changes.” Also, Intel’s supply chain “comprises more than 19,000 suppliers in over 100 countries.”7,8

Thirdly, the semiconductor industry is known for very short innovation and new product development cycles. Actually, according to multiple reports, the industry was “ranked 2nd most innovative manufacturing industry in the US.”9 Since this innovation directly affects the product development process, manufacturers are constantly pressured to migrate towards more agile supply chains.

Intel adopts a three-pillared solution

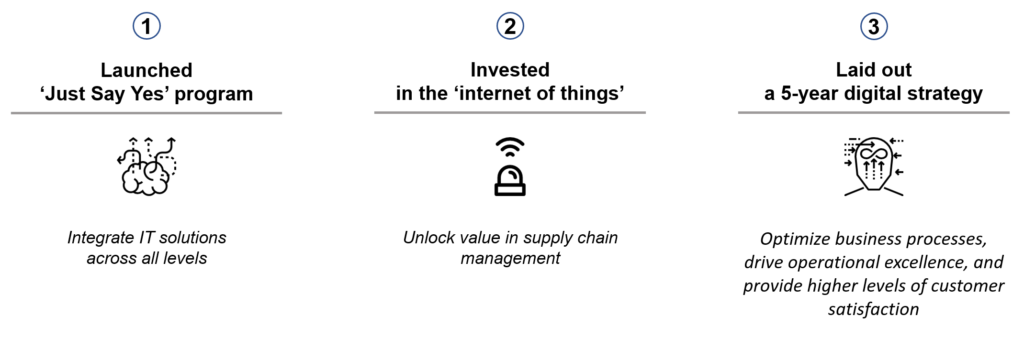

Intel quickly recognized the necessity to optimize its supply chain through digitalization. As such, Intel launched the ‘Just Say Yes’ program to “integrate IT solutions across all levels”7; it also invested in the ‘internet of things’ to “unlock value in supply chain management”10; and developed a 5-year digital strategy to “optimize business processes, drive operational excellence, and provide higher levels of customer satisfaction.”6 By integrating IT solutions in its supply chain, Intel reduced new manufacturing process ramp up time by 50%, decreased order-fulfillment lead time by 65%, and lowered inventory levels by 32%.7 Similarly, Intel’s investments in the ‘internet of things’ enabled “improved supply chain logistics planning,”10 and thus reduced time spent loading freight containers, as well as improved handling accuracy. Finally, Intel’s digital strategy unlocked real-time decision-making by leveraging big data and enabling manufacturing components to ‘sense-and-respond’ on the spot. Through this strategy, Intel aims to “improve end-to-end visibility” and create a ‘glass pipeline’ supporting “real-time analytics, real-time data, and real-time processing.” Moreover, this approach allows Intel to “implement advanced algorithms to enable deep analysis and correlation of data from disparate sources, both structured and unstructured.” Also, this supply chain transformation strategy will simplify the manufacturing process and allow Intel to “coalesce all data elements and key supply chain metrics into a single version of truth.”6

Additional considerations for Intel

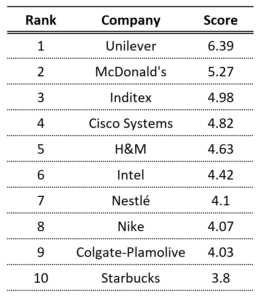

Given Intel’s actions to digitize its supply chain, it “entered the Garner Supply Chain Top 25 in 2009 at the rank of 25.7 In 2017, Intel became the 6th best manufacturer in terms of supply chain best practices”11 as shown in Exhibit 4. Accordingly, Intel risks focusing too much on improving current processes and refraining from experimenting with innovations on the process design level. Going forward, Intel should institutionalize the ‘bimodal’ practice of “managing two separate but coherent styles of work: one focused on predictability (improving well-understood areas); the other on exploration (experimenting to solve new problems).”12 Moreover, Intel should further invest in vertical integration by consolidating suppliers and integrating their systems with its own. Through real-time data sharing, Intel can improve its procurement efficiency, optimize just-in-time ordering, and enhance both its operations and those of its suppliers. Finally, Intel can capitalize on advancements in 3D-printing and integrating that in its manufacturing processes. According to a Strategy& report, this technology promises to “revolutionize warehousing and distribution of spare parts”, since it allows for “spare parts to be manufactured as needed at facilities maintained locally – even on-site, if demand is high enough.”13

Looking ahead

In conclusion, Intel is embracing the digitalization of supply chains to lead the highly competitive semiconductor industry. To sustain this leadership, Intel will need to stay at the forefront of supply chain innovation, both internally and externally. One potential internal innovation is leveraging real-time manufacturing data in research and new product development. Will this data availability decrease overall R&D costs? Externally, Intel can investigate whether blockchain can unlock vertical integration with its suppliers. Can blockchain be the solution to protect data privacy and security while also allowing for real-time data sharing?

(799 words)

Sources:

1 Wellesley College. (2015, May 4). Rapid innovation in semiconductors provides hope for better economic times. ScienceDaily. Retrieved November 15, 2017 from ScienceDaily.com: www.sciencedaily.com/releases/2015/05/150504094322.htm

2 Statista. (2017). Semiconductor industry sales worldwide 1987-2019. Retrieved November 15, 2017 from Statista.com: https://www.statista.com/statistics/266973/global-semiconductor-sales-since-1988/

3 Gartner, Inc. (2017, January). Gartner Says Worldwide Semiconductor Revenue Grew 1.5 Percent in 2016. Retrieved November 15, 2017 from Gartner.com: https://www.gartner.com/newsroom/id/3573717

4 O’Marah, K. (2016, November 17). Digitization In Supply Chain: Five Key Trends. Forbes. Retrieved November 15, 2017 from Forbes.com: https://www.forbes.com/sites/kevinomarah/2016/11/17/digitization-in-supply-chain-five-key-trends/#7ffde06428ad

5 Clark, D. (2015, June 01). Corporate news: Margin, pricing pressures behind chip-merger wave. The Wall Street Journal. Retrieved November 15, 2017 from The Wall Street Journal Asia: http://search.proquest.com.ezp-prod1.hul.harvard.edu/docview/1684310431?accountid=11311

6 Intel. (2017, September). Transforming Intel’s Supply Chain with Real-Time Analytics. Retrieved November 15, 2017 from Intel.com: https://www.intel.com/content/dam/www/public/us/en/documents/white-papers/transforming-supply-chain-with-real-time-analytics-whitepaper.pdf

7 Intel. (2012, January). Transforming Intel’s Supply Chain to Meet Market Challenges. Retrieved November 15, 2017 from Intel.com: https://www3.intel.com/content/dam/www/public/us/en/documents/best-practices/transforming-supply-chain-to-meet-market-challenges.pdf

8 Intel. (n.d.). Supply Chain Responsibility at Intel. Retrieved November 15, 2017 from Intel.com: https://www.intel.com/content/www/us/en/corporate-responsibility/supply-chain.html

9 Fujiki, C. (2015, August). The U.S. Semiconductor Industry is one of the Most Competitive Manufacturing Industries in the United States. Retrieved November 15, 2017 from semiconductors.org: http://www.semiconductors.org/clientuploads/Industry%20Statistics/U.S.%20Semiconductor%20Industry%20Competitiveness%20White%20Paper%20-%20Final%20for%20posting%20-%2008042015.pdf

10 Intel. (2016, October 14). Innovative IoT Technologies Unlock Value in Supply Chain Management. Retrieved November 15, 2017 from Intel.com: http://blogs.intel.com/iot/2016/10/14/innovative-iot-technologies-unlock-value-supply-chain-management/

11 Gartner, Inc. (2017, May 25). Gartner Announces Rankings of the 2017 Supply Chain Top 25. Retrieved November 15, 2017 from Gartner.com: https://www.gartner.com/newsroom/id/3728919

12 Gartner, Inc. (n.d.). IT Glossary – Bimodal. Retrieved November 15, 2017 from Gartner.com: https://www.gartner.com/it-glossary/bimodal/

13 Strategy&. (2016). How digitization makes the supply chain more efficient, agile, and customer-focused. Retrieved November 15, 2017 from strategyand.pwc.com: https://www.strategyand.pwc.com/media/file/Industry4.0.pdf

An interesting take on the things Intel has already done to digitize its supply chain. On the subject of using 3D printing to help reduce the supply chain, I’m interested to know what part of the product could be manufactured this way–the logic gate dimensions on microchips are on the scale of 5 nanometers best 3D printers today have a minimum resolution of about 20 microns (20,000 nanometers). Do you think that portions of the chip’s housing or heat sinks could be 3D printed, or do you envision that 3D printing will eventually get to nanometer-scale resolutions?

You bring up some great points about a company who has been at the forefront of digitization from the beginning. I anticipate Intel will continue to be a company that the world will look to as an example of how to incorporate the “internet of things” along with other supply chain improvement strategies into their business model. Do you foresee Intel partnering with any other companies, or investing in other technologies in addition to blockchain?

Wonderful graphics and bringing light to something that’s in front of our faces, but rarely talked about. It was lovely learning about Intel’s innovation in semiconductors, a technology that we use daily yet is hidden (literally, within hardware, and within discourse). I’m curious: do you think that Intel has an “edge” in terms of innovation? Do you think the advancements they’ve made and historical culture of innovation count as a competitive advantage, especially now that the world sees what they have done and how they operate? It will be interesting to see if Intel continues to operate at the forefront of semiconductor innovation in an increasingly fast, digital world where, as you note, information sharing and product innovation cycle times are increasingly decreasing.