Digital Sushi: How Blue C Is Innovating the Restaurant Industry

Blue C is optimizing Just-In-Time delivery to better serve customers, and better manage food production.

Radio-Frequency Identification (RFID) is changing the way inventory is managed across the world. Serialized tags or chips are embedded or attached to inventory, databases are integrated between inventory locations and retail locations, and managers have real-time data on a full spectrum of inventory metrics.[1]

Transmitters and computers are required hardware involved in the data transmission process. Transmitters, or RFID readers, are appropriately placed to only interact with chips once the inventory is moving from one location to another, sending a signal to a transmitter via radio frequency waves, then sending data to a linked computer.2

RFID technology is not just utilized for increasing accountability for inventory as it moves through the supply chain. It also provides a new set of data involving how quickly inventory moves throughout each step of the chain, specific inventory that remains stagnant (no demand), and how many employees interacted with that item along the way.3 Furthermore, customers can now benefit from RFID technology.

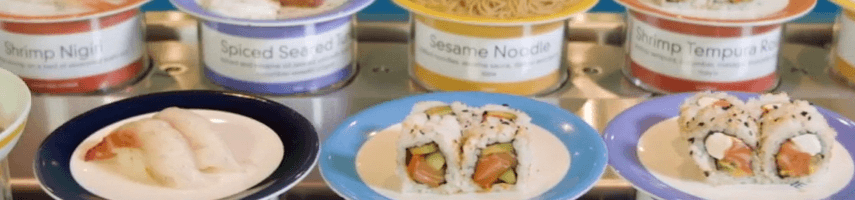

Blue C Sushi, established in Seattle with locations in Washington and California, is bringing RFID straight to the table. Blue C promises to bring sushi to customers with the speed, frequency, and color spectrum of the Tokyo subway. 4 Executing this style of offering to customers comes with a cost: a micromanagement of inventory (sushi) available every minute to perfectly match customer demand. In an industry of slim margins and desire to minimize food waste, Blue C sought to revolutionize the buffet restaurant industry by bringing technology to assist with inventory management to maximize profits, minimize waste, and ensure the best customer experience.

Each plate, individually prepared, is embedded with an RFID chip. The plates are placed on a revolving belt that passes by customers. When the plate is removed from the belt, a signal is sent from the plate to the RFID reader to the kitchen, alerting the chefs to prepare another similar plate to replenish the belt. Similarly, a plate that sits on the delivery belt too long is tracked by the kitchen to signal a lack of demand and potentially a plate that is no longer safe for consumption.5 This is not Blue C’s first attempt to bring technology into the restaurant. They first experimented with barcode technology. The barcode system was only effective in the food safety element of ensuring sushi had not been out on circulation for more than 90 minutes. A manager could infer demand on that data, but there was also so much information valuable to a chef. 6 Blue C waited for RFID technology to be more affordable, but still took considerable efforts to integrate it into the kitchen, when it had previously been only in warehouse settings. Chip adhesion that withstand sanitization cycles and normal wear and tear meant cross-industry coordination with 3M to ensure the product had longevity. 7

Going forward, Blue C is ahead of the curve in integrating this capital-intensive technology into its supply chain. Most businesses use this technology on a global scale, but Blue C has transformed the intent to perfect just-in-time delivery, reduce waste, and ensure consumer safety is maximized. Blue C has built an operating model on the trust that this system functions properly 100% of the time. In this case, it is less risky given the assumed skillset to revert back to individual order management. Optimistically, Blue C could encourage this technology to permeate their entire supply chain from sea-to-table. Customers may find significant value in knowing where the fish on their plate originated from. The simplest answer is to tag every fish as it is sold at market, and track it to the table. Blue C is setting the precedence in the restaurant industry for an increased complexity in data management. Will anyone else be willing to take the leap into the digital age of dining? (655 words)

[1] Intel Corporation, “Inventory Optimization Solutions Drive Revenue and Profitability,” http://www.intel.com/content/www/us/en/retail/driving-revenue-through-inventory-optimization.html,” accessed November 2016.

2 Sonia A. Joseph, and Joby N. J., “Analyzing RFID Tags in a Distributed Environment,” Procedia Technology, Vol 24, 2016, pp. 1484-1490.

3 Intel Corporation, “Inventory Optimization Solutions Drive Revenue and Profitability,” http://www.intel.com/content/www/us/en/retail/driving-revenue-through-inventory-optimization.html,” accessed November 2016.

4 Blue C Sushi, “How It Works,” http://www.bluecsushi.com/HowItWorks/default.aspx, accessed November 2016.

5 Blue C Sushi, “About Us,” http://www.bluecsushi.com/AboutUs/default.aspx, accessed November 2016.

6 RFID Update, “Sushi Restaurant Swimming in Benefits from RFID,” RFID Journal, May 17, 2007.

7 Ibid., RFID Journal, May 17, 2007.

Wow this is crazy! I have never heard of this technology and certainly didn’t expect to see this sort of digitization of dining! I can see how RFID assists managers across many industries help manage inventory and costs. However, I am a little skeptical of how RFID is being used at Blue C and whether this is really the correct way to bring technology to the restaurant experience. First, this sounds really expensive! Did you turn up any research on how this affects overall costs for the restaurant and price for the consumer? I imagine there are significant savings in food waste and inventory management, but I also imagine the technology is expensive and that the consumer ultimately bears that cost. Second, this feels a little invasive to a dining experience. It feels like a computer is serving me food and monitoring my eating, which personally, would dissuade me from becoming a patron of Blue C. It will be really interesting too see how this develops!

Thanks for the interesting read! I, too, was definitely unaware that RFID technology was being deployed in this context. Has Blue C conducted analysis to determine the magnitude of the cost savings (in better inventory management, more accurate demand fulfillment, potentially reduced labor needs, etc.), or is it too early to say? Also, it’s interesting that a restaurant operator itself (rather than a restaurant software vendor or technology provider) is the one building out this system. Has Blue C considered licensing or otherwise monetizing its expertise in food-service RFID solutions deployment? I am excited to see how this develops!

Loved this innovation brought by Blue C Sushi! Such a smart move to, as you have mentioned in the article, minimize waste and better serve their clients.

As a sushi-lover, I do have concerns about raw food being exposed for too long on restaurants. RFID technology adopted by Blue C Sushi will definitely improve food safety concerns. I found very interesting how the restaurant, even though with low margins, managed to employ technology on its front and back offices. I guess the main challenge here is making it profitable and leverage the learnings to the restaurant supply chain. Well, this won’t be an easy task as restaurant business is known for its tradition and technology aversion!

Great article!

So nice to see this blog post since this RFID technology adopted by Blue C Sushi is extremely common in Japan. Sushi restaurants that adopt this is called “Kaitenzushi” – where you could eat sushi in the most efficient manner (quick and fresh). However, I do wonder how long it would take these sushi restaurants to payback its investments, considering its low margins.

Fascinating post, Anja! I was also not aware of this technology and similarly to the posts above I also wonder how financially feasible it is for a low-margin business to adopt this model.

I would think that large buffet style restaurant chains would have an operating model that could benefit from such a technology at a larger scale and absorb the costs. Did you by any chance come across any other use cases in the dining industry?

Additionally, I am curious whether this has been applied in any other industries where savings in inventory management costs could be quite significant. I came across an interesting article that discussed the use cases in the retail industry [1]:

– Continuous “live” store inventory reporting that enables retailers to get real-time detailed information on their stock through an on-going automatic scan system in warehouses and stores (versus doing a manual check by an employee)

– Simultaneous “one shot” scanning of goods at the cash which makes it possible to scan everything in a consumer’s grocery cart at once, while still in the cart (eliminates need to remove items for check-out)

It looks like these applications are in pilot stage yet and other uses that have been suggested include loading airport bags or identifying counterfeit drugs in the pharmaceutical industry. What do you think about these applications and did you come across any others?

[1] http://www.ic.gc.ca/eic/site/oca-bc.nsf/eng/ca02320.html