Combating Digital Darwinism: Four Eyes on Augmented Reality

This is a time of digital Darwinism — an era where technology and society are evolving faster than businesses can naturally adapt. Can DHL a leading global logistics company rise up to the challenge to remain competitive?

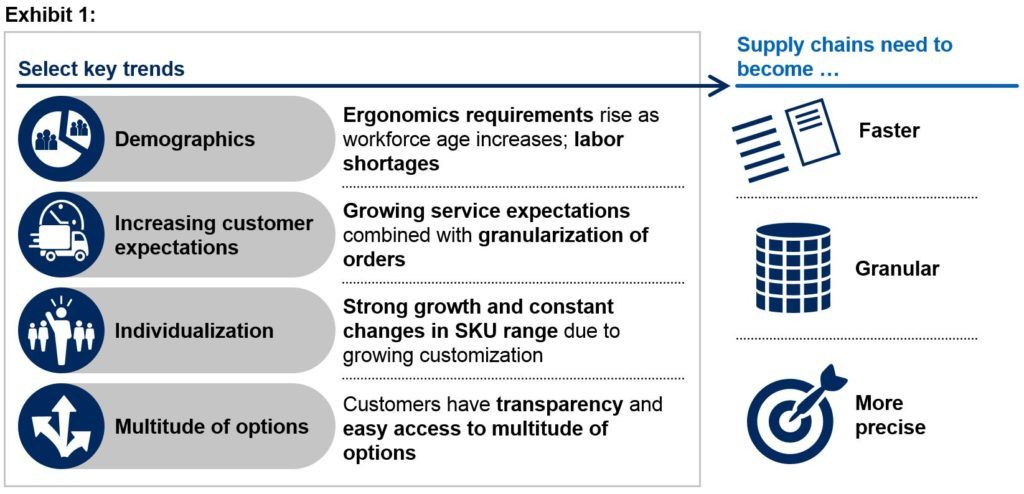

The world is changing – growing customer expectations, individualisation, and demographic changes are influencing the way we need to run supply chains (SCs). SCs need to become faster, more granular, and increasingly precise compelling organisations to adapt or face the risk of digital Darwinism (Exhibit 1). Many firms are turning to disruptive digital technologies to facilitate productivity gains, enable new business models, and fundamentally change the way SCs operate to remain competitive.

Managers at DHL embraced the digital revolution to meet increasing customer service expectations and the granularization of orders through on-line trend. This impetus to act is compounded by growing customization/individualization as SKU ranges grow across industries. [1] Internally, DHL managers are facing ageing populations and potential labour shortages in the in the developed world. Notably, the US Census Bureau predicts that more than 60 million “boomers” will exit the workforce by 2025, whilst only 40 million will take their place. [2] Facing an ageing workforce, DHL must act swiftly to bridge the gap between new recruits and existing staff via ergonomic innovations.

Leveraging AR in the face of digital Darwinism

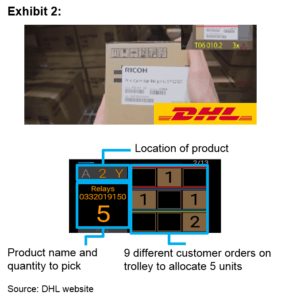

DHL are enhancing human-machine interactions by rolling-out augmented reality (AR) glasses in warehouse picking operations which are estimated to account for 55-65% of total warehousing costs. [3] Pickers are equipped with AR glasses which display the location of each item and where it should be placed on the trolley (see Exhibit 2) resulting in ~15% efficiency gains, increased employee satisfaction, and reduced error rates. [4] Although picking errors rates are very low, estimated at 0.35% using pick-by-paper methods, every error must be prevented as it typically results in high follow-up costs. [4] Digitally enhancing the picking process has increased the speed and precision of the SC to meet growing external demands, whilst improving productivity to relieve internal labour pressures.

In the medium term, managers are looking into additional applications for AR including trainings/dimension calculations. Most notably, DHL is testing the application of AR in planning processes as warehouses are increasingly used to house additional value-added services (e.g., product assembly/labelling) hubs must adapt to accommodate for new services. [5] Modifications are overlaid in the real environment to ‘field test’ adjusting planned redesign measures via AP to support and reduce the cost of warehouse redesign and planning.

Expanding beyond human-machine interactions, DHL is considering applying Internet of Things (IoT) into its warehousing operations to optimize efficiency in real-time via responsive graphical visualizations of operational data aggregated from sensors on scanners, material handling equipment, and warehouse management systems. By 2020 there will be 50 billion connected devices [6] with the potential to streamline employee operations, and trace goods through the SC improving employee safety whilst generating significant efficiencies.

Recommendations for a long-sighted strategy

To complement the deployment of disruptive digital technologies across the SC, DHL must run extensive training programmes to ensure employees are part of the change. [7] Upskilling the workforce expertise to match advancements in technology is crucial to capitalising on digitalisation opportunities. Moreover, if employees are not encouraged to embrace new ways of working in the SC, the change may be met with resistance.

DHL should continue innovating to identify additional AR applications across the SC (i.e., beyond warehouse operations). For instance, AR has the potential to optimise transportation completion checks required to register a delivery as complete and ready for pick-up. AR devices could capture pallet/parcel numbers, and volumes using markets or object recognition technology to accelerate checks. More generally, DHL could investigate new forms of human machine interaction allowing machines and humans both work in closer proximity and machines can ease previously strenuous tasks for humans. An example is the Festo ExoHand, which emulates the physiology of the human hand and can support straining manual movements (worn as glove) and transmit human hand movements to robot hand. [8] As a result workers can remotely pick up products – picker sits in remote location and directs robots – enabling the remote handling of dangerous goods.

Going forward there are several questions for DHL. Whilst AR is already providing tangible benefits across multiple industries, have we overcome the technical and societal challenges including high investment costs, network performance issues and public acceptance necessary for wide adoption?

Moreover, the high cost of AR solutions means many organisations (including DHL) are obtaining core software from open source platforms to reduce costs. This runs the risk of inadvertent or targeted exposure of coding and ultimately information to third parties. As regulations continue to lag behind technological developments/adoption, will corporate and government insurance frameworks prove effective in dealing with new forms of crime? How can DHL mitigate against these concerns?

Word count: 798

[1] McKinsey & Co., Supply Chain 4.0 in Consumer Goods, April 2017

[3] De Koster, René et.al. (2006): Design and control of warehouse order picking: A literature review. European Journal of Operational Research.

[4] DHS Press Release – February, 2017 “DHL Supply Chain makes smart glasses new standard in logistics

[5] DHL, “Augmented Reality in Logistics – changing the way we see logistics – a DHL perspective”, 2014

[6] Mobile World Live, “DHL: Adding digital logic to logistics – Mobile World Live”, 2017

[7] Supplychaindigital.com, “Training workforces in digitisation of the supply chain: Q&A with DHL | SCM | Supply Chain Digital”, 2017

[8] Festo Website. “ExoHand – Human-machine Interaction.” 2015

Although both AR and VR are in their infancy stages, I believe that AR is more likely to achieve wider adoption and social acceptance. This is because AR is generally seen as a technology that can complement and augment normal human actions, whereas VR is seeking to replace or completely redefine how we perceive reality itself.

To deal with potential security issues related to the acquisition and use of open source AR software, DHL needs to set up the necessary organizational structure to deal with these risks. As the Company relies more on technology in its daily operations, it needs to realize that it is no longer just a logistics and delivery business. Having in-house developers and cyber security experts (or outsourcing such tasks to qualified professionals) may be necessary for the Company to conform to potential future regulations and mitigate against the risk of crimes.

Very interesting read! While AR seems to be inevitable in logistic companies, because it increases labor efficiency in an aging labor force, there are two points I would like to raise.

First, in order to realize the full potential of AR in the short run DHL needs to make sure that its operating system is digitalized accordingly. In 2014 General Electric has launched an effort in Germany to equipment maintenance workers with AR glasses to facilitate their maintenance work. GE has failed to integrate the AR system into their old operating system . For certain operations workers needed to input information twice – once for the AR system and once for the GE operating system. As a result, the overall efficiency of the worker decreased while the efficiency for the actual maintenance work increased.

Second, in the long run I think that logistics companies should aim for full automation of the supply chain. For instance, DHL can draw inspiration from Amazon’s fully automated Kiva picking system.

I would never have imagined the application of AR to DHL. This is so creative. I totally side with you on the fact that there will be challenges towards wide-scale adoption. I think the biggest solution here is actually time. Time will help with digital advancement. Time will help with the cost. Time will also help with public acceptance. Since AR or IoT will probably not be DHL main business, I think it wouldn’t be worthwhile for DHL to make any investment now. To wait for time and to learn more about the application, best thing DHL can do is to continue testing small-scale pilot projects of the technology.

Besides improving workers productivity and accuracy, another benefit I think DHL can utilize AR is to improve the employee work enjoyment. This might sound a little bit too unconventional but I think there is an opportunity to implement gamification through AR here. To elaborate, DHL can provide options for employees to opt in game mode and compete in teams to achieve maximum speed or a maximum number of product picked. Points can be calculated with number of product and seconds of time. To maintain the rate of accuracy, points will be greatly reduced if the action is incorrect. I think this a very creative way to make a boring job very attractive. It should help DHL with employee retention and attract the higher number of candidates for the job.