Caterpillar: Building the Supply Chain of the Future

Caterpillar is using data and analytics to manage its complex supply chain and reduce costs.

Why does Caterpillar want to digitalize its supply chain?

Across industries, companies are racing to transform themselves by embedding digital technology into their operations, and organizations that are slow to do so risk falling behind. A recent Gartner analysis of supply chains identified digitalization as a key focus area for industry-leading companies like Apple, Proctor and Gamble, and Amazon [1]. These technologies help organizations access real-time information across the supply chain and react more nimbly, empowering them to make decisions that lowers costs and improves service like reducing waste and shortening lead times.

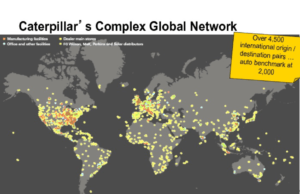

Caterpillar, one of the world’s largest manufacturers of heavy machinery, manages an extremely complex network of suppliers, manufacturing facilities, and customers [Figure 1]. This unwieldy network is difficult to manage in perfect conditions, and doubly so when the supply chain is disrupted. For example, natural disasters require companies to accurately identify production or inventory issues and work around them to meet demand. Issues like this are common, with ~40% of North American supply chain executives facing a disruption of some kind over the last year [2].

Additionally, Caterpillar’s core machinery business is highly susceptible to macroeconomic conditions. In poor economic times, demand for the company’s core construction equipment plummets, significantly reducing profitability for the company and underscoring the need for effective variability management in the supply chain.

What is the company doing?

Caterpillar is currently working on an initiative to establish end-to-end visibility across the supply chain [3]. Since launching the initiative, the company has been able to reduce their inventory by over $250M [4]. Digitization is a key part of this, and the company has made extensive use of embedded sensors to gain greater visibility into its in-transit inventory.

These sensors have lowered the company’s costs and helped it maintain steady gross margins during economic downturns. The sensors are attached to products like bulldozers as they move across the supply chain, giving the company increased visibility over where its inventory is at all times. This helps the company recognize when bottlenecks are building and make better decisions about how to respond. For example, after a 2015 fire in one of its facilities led to a halt in production, Caterpillar collected data from its supply chain and determined it had enough inventory in transit to meet demand without boosting output at other plants [5].

To date, Caterpillar’s focus on incorporating digital tools into the supply chain has focused on managing variability, managing disruptions, and reducing inventory costs. In the future, Caterpillar aims to be more proactive and use data to predict the health of equipment, productivity, and sales in order to optimize the structure of their supply chain [6]. Caterpillar is also partnering with industrial digital technology startups like Uptake to co-create digital solutions [7] and investing in R&D to develop innovative technology [8].

What else should the company be thinking about?

Though the company has far worked to incorporate digital technology into its supply chain, most of the work has focused on improved inventory visibility and data analytics for internal use.

As a next step, Caterpillar should consider additional innovations like additive manufacturing that are helpful in their own right but also build on Caterpillar’s digital infrastructure. For example, in the event of a supply chain disruption, managers could decide to 3D print certain components instead of routing them from another part of the supply chain, provided the 3D printing is more cost effective. To make this decision, Caterpillar would need data from the digital systems it’s currently implementing.

Additionally, Caterpillar could look to more tightly link its supply chain with its customers, providing them with greater visibility and data into their orders. Just as Caterpillar appreciates knowing where its inventory is at every step of the supply chain, customers can make use of improved and real-time data to better manage their own supply chains and plan for potential disruptions.

Open questions

Like many companies, Caterpillar is hard at work digitally transforming its supply chain, but several important questions remain:

-How should Caterpillar identify new technologies? Should it look to do more in-house development, like with its innovation labs, or should it do more external searching, like with its start-up partnerships?

-How should Caterpillar think about the decision to investigate new technologies? For example, many companies are automating previously manual tasks with tools like drones, but how would Caterpillar determine if it should use drones its supply chain?

Word Count: 736

Sources:

[1] Aronow, Stan, Kimberly Ennis, and Jim Romano. 2017. “The Gartner Supply Chain Top 25 For 2017”. Gartner.Com. https://www.gartner.com/doc/3728317?refval=&pcp=mpe.

[2] GT Nexus. 2016. “State of the Global Supply Chain”. gtnexus.com

[3] France, Tom. “Visibility in the cloud”. https://ieondemand.com/presentations/visibility-in-the-cloud-07-11-2013

[4] “3 Problems CAT Solved To Save $250 Million In Excess Inventory”. 2017. GT Nexus. http://www.gtnexus.com/resources/blog-posts/cat-saved-250-million-in-excess-inventory.

[5] “Caterpillar’s Internet-Connected Sensors Steady Profit In Downturn”. 2017. Digital Commerce 360. https://www.digitalcommerce360.com/2016/07/26/caterpillars-internet-connected-supply-chain-steadies-profits/.

[6] Reiss, Robert. 2015. “Supply Chain Leaders Share How Digital is Transforming Operations”. Forbes.com. https://www.forbes.com/sites/robertreiss/2015/12/07/supply-chain-leaders-share-how-digital-is-transforming-operations/#148952294b04.

[7] Caterpillar And Uptake To Create Analytics Solutions”. 2017. Caterpillar.Com. http://www.caterpillar.com/en/news/corporate-press-releases/h/caterpillar-and-uptake-to-create-analytics-solutions.html.

[8] Caterpillar Announces Grand Opening of First Data Innovation Lab”. 2017. Caterpillar.Com. http://www.caterpillar.com/en/news/caterpillarNews/innovation/caterpillar-announces-grand-opening-of-first-data-innovation-lab.html

This is an interesting subject. I would like to add that Caterpillar’s digital technology has advantage against it’s key competitor, Komatsu. The system between the two companies differ largely by their coverage. While Komatsu only controls their own construction equipment, Caterpillar traces other manufacturer’s construction equipment together. From the end-users view (e.g. construction companies, mining operators), the latter is much more valuable because it enables a holistic project management. If Caterpillar can improve it’s digitalization based on end-user’s needs in addition to their own supply chain management, we may see the company evolve their already dominant position in the market.

In response to your question about sourcing innovations, I have a deep belief that in order to best align; these innovations need to come from within. There is a great HBR article that calls on these “Intrapreneurs” who are more equipped to hack the current system [1]. Their repetitive usage of the existing system gives them the insight they need in order to create creative solutions. Often times, these individuals will also have knowledge beyond the product, but also how it is used in the company’s system. Extensive knowledge is crucial in ensuring wide adoption of the product. With that said, it is the company’s job to not only encourage such behavior but also remove obstacles and barriers towards innovation from within.

[1] https://hbr.org/2016/06/what-it-takes-to-innovate-within-a-corporate-bureaucracy

In your closing, you mention Caterpillar integrating more closely with its customers. Companies that purchase Caterpillar equipment are likely quite brand loyal. Therefore, tracking a piece of equipment’s usage and efficiency over time could deliver Caterpillar valuable insights into when a customer will need to reorder spare parts and replacement heavy equipment. Essentially, Caterpillar would gain a clearer picture of demand and so be able to more efficiently schedule its production.

Caterpillar’s results from integrating end-to-end visibility into their supply chain resulted in over $250M of savings. This is a solid first step towards reaping the benefits of digitalization. It does seem, however, that the company is already integrating 3D printing technologies into the design of their systems. It recently opened a 3D Printing & Innovations center. Additionally, it announced a partnership in 2017 with AM solutions provider FIT AG.

To further this trend, Caterpillar should continue to invest heavily in technology solutions to improve its supply chain. Partnerships, incubators, and venture capital divisions will all be good ways to progress the company’s foothold with emerging technologies.

https://3dprint.com/168282/caterpillar-fit-ag-partnership/

https://www.caterpillar.com/en/news/caterpillarNews/innovation/caterpillar-announces-grand-opening-of-3d-printing.html