Adidas’s Race to be #1 in 3D Printing

Adidas is investing heavily in additive manufacturing, partnering with Silicon Valley's Carbon Inc to one day produce 50 million pairs of 3D printed shoes per year.

“The plan will put us as the (world’s) biggest producer of 3D-printed products.” -James Carnes, VP of Strategy Creation, Adidas[1]

In September of 2017, Adidas overtook Nike’s Jordan brand as the second largest sneaker brand in the US[1]. Although Adidas is still a distant second to Nike, the sportswear industry is more competitive than ever, spurring innovation throughout the footwear industry, with Adidas now looking to 3D printing for its midsole production process. Midsole cushioning technology has always been at the center of footwear innovation with Nike introducing “Air” in its midsoles in 1978 with technology developed by Nasa engineers[2]. More recently, Adidas has partnered with German chemical giant BASF for their “Boost” midsole material.

In September of 2017, Adidas overtook Nike’s Jordan brand as the second largest sneaker brand in the US[1]. Although Adidas is still a distant second to Nike, the sportswear industry is more competitive than ever, spurring innovation throughout the footwear industry, with Adidas now looking to 3D printing for its midsole production process. Midsole cushioning technology has always been at the center of footwear innovation with Nike introducing “Air” in its midsoles in 1978 with technology developed by Nasa engineers[2]. More recently, Adidas has partnered with German chemical giant BASF for their “Boost” midsole material.

Aside from material innovations, sportswear companies such as Nike and Adidas utilize strategic partnerships to gain market share. In 1928, just four years after making his first pair of shoes in his mother’s kitchen, Adidas founder, Adolf Dassler partnered with Olympic runner, Lina Radke. More recently, Adidas has broadened its partnerships to include World Cup organizer FIFA, rapper Kanye West, and NBA player James Harden. With the latter in a sponsorship deal worth over $200 million.

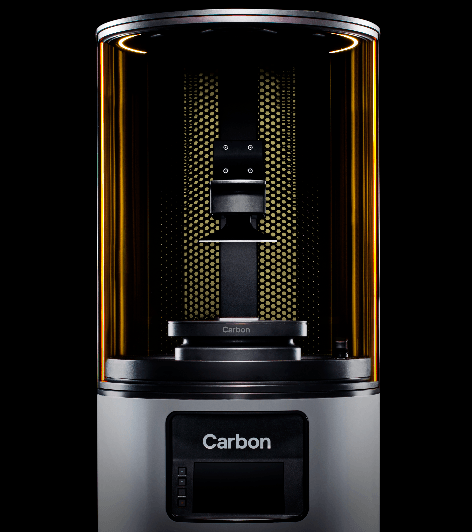

“A software-controlled chemical reaction to grow parts” -Joseph DeSimone, Founder & CEO, Carbon[3]

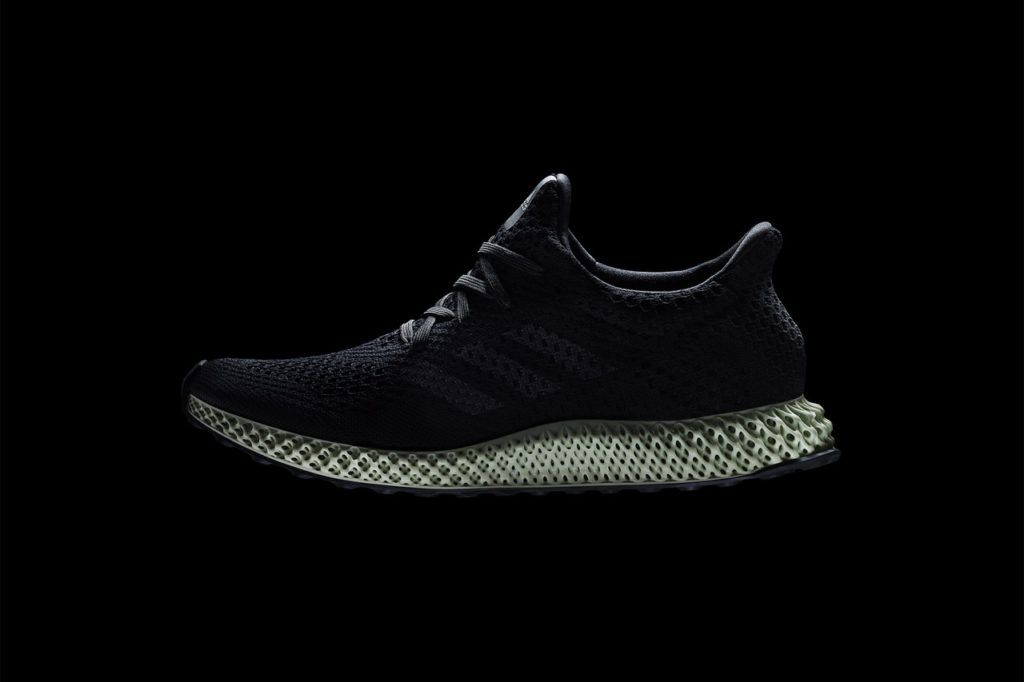

Adidas’s newest partnership: Silicon Valley tech firm, Carbon Inc. Carbon’s technology can be summarized as a type of stereolithography called Digital Light Synthesis (DLS), where lasers cure 3D shapes from pools of resin. However, Carbon’s propriety machines produce up to 100 times faster compared to traditional 3D printing and can be applied to a wider variety of materials[4]. Moreover, Carbon’s business model is unique, electing to lease out its machines as opposed to selling them outright, reducing upfront costs and encouraging faster adoption of a new technology.

As of July 2018, Carbon has raised $422 million from investors such as Johnson and Johnson, Google Ventures, Sequoia, and Adidas at a valuation of $1.7 billion. As part of the deal, Adidas acquires exclusive access to use Carbon’s technology in sportswear.

“The vision is to build and print on demand,” – Eric Liedtke, CMO, Adidas[5]

The promise of 3D printed shoes means personalized shoes for every foot[6]. The dream is for a customer to walk into a retail location, get their foot scanned and walk out with a newly printed pair of shoes. Furthermore, production sites can move closer to customers, thereby reducing inventory and transportation costs. Everything is controlled by software, so prototyping and product cycle times will inevitably be shortened.

Within the short term, Adidas plans on opening up two “Speedfactories”—one in Ansbach, Germany and the other in Atlanta—to further test their new production model[7]. While Carbon and Adidas have already made significant gains in unit production times (90 to 30 minutes), the ultimate goal is 15 minutes. This decrease in production time will assist Adidas’s goal of increasing production volumes. Last year, Adidas produced approximately five thousand pairs of 3D printed sneakers. In 2018 total production increased to one hundred thousand pairs. In 2019, the goal is one million pairs. One day, Adidas is hoping to produce up to 50 million pairs of 3D printed shoes—approximately 10% of Adidas’s total production[8].

Beyond ramping up production, the promise of a 3D printed shoes must benefit the consumer, namely in areas of performance. Once the technology is mature, Adidas needs to refocus on its core competency: professional athletes and data collection. Partnering with a variety of pro athletes will give 3D printed sneakers the performance credibility that consumers demand. Furthermore, the diversity in athletes is critical. Putting this new technology within different sports will prove out the wide applicability of 3D shoes. The shorter product development cycle lends the possibility of faster product improvement. Adidas needs to invest heavily into more research on how different athletes perform with incremental changes in the shoes; perhaps, printing microsensors in the shoes themselves.

Even given near-perfect execution on these strategic objectives, there is still the question of market demand. The Futurecraft 4D retails for $400 with even higher prices in the secondary market. Although Adidas has a history of pushing the boundaries on what customers are willing to pay for a pair of sneakers, will the 50 million pairs they plan to produce annually sell through? Moreover, will Adidas ever realize true athletic performance gains over traditionally produced sportswear? Or is this just fad that will inevitably blow over? (784 words)

[1]Cheng, 2018. How Adidas Plans on Bringing 3D Printing to the Masses. https://www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential/#6c98352b4a60 accessed November 12, 2018.

[2]Flower, 2017. Is Mass Customization the Future of Footwear? https://www.wsj.com/articles/is-mass-customization-the-future-of-footwear-1508850000 accessed November 12, 2018.

[3] Estes, 2018. The Absurd History of Nike Air Technology. https://gizmodo.com/the-brilliant-but-absurd-history-of-nike-air-technology-1741712594 accessed November 12, 2018.

[4]Tullo, 2018. 3-D Printing Start-up Carbon Seeks to be Found Everywhere. https://cen.acs.org/materials/3-d-printing/3-D-printing-startCarbon-seeks/96/i27 accessed November 12, 2018.

[5]Markillie, 2017. 3D Printing the Factory of the Future. https://www.economist.com/briefing/2017/06/29/3d-printers-start-to-build-factories-of-the-future accessed November 12, 2018.

[6] Dillet, 2018. How Adidas and Carbon are Changing the Sneaker Supply Chain. https://techcrunch.com/2018/09/07/how-adidas-and-carbon-are-changing-the-sneaker-supply-chain/ accessed November 12, 2018.

[7] Mims, 2018. Your Shoes will be Printed Shortly. https://www.wsj.com/articles/your-shoes-will-be-printed-shortly-1494763201 accessed November 12, 2018.

[8] Kim, 2018. Adidas’ Vision for the Future: Personalization Fast. https://money.cnn.com/2018/07/06/technology/adidas-speedfactory/index.html accessed November 12, 2018.

I really enjoyed this post as I had no clue Adidas was 3D printing shoes before reading this! I think Adidas partnership with Carbon is very forward-looking, and I’m impressed with their ability to secure exclusivity in the use of these machines within the sportswear space. I’d be interested to learn more about what competitors to Carbon exist and if they have developed partnerships with rival brands like Nike, or if Nike plans to bring its 3D printing capabilities (assuming it is also pursuing additive manufacturing) in-house. I also think your questions about price are spot-on. While the use of additive manufacturing in the production process will likely speed up the process and make it more efficient and thus less costly, I would assume in the near-term at least, Adidas will charge more for customized shoes, so it will be interesting to see if they change their target market for their 3D printed products.

Well it looks like Carbon’s technology is pretty advanced. So I’m not sure which other companies are directly competing against Carbon’s production speed and material flexibility. It has to do with a permeable window that let’s oxygen through and slows down curing at the bottom of the tank. This allows for both UV and Thermal curing. Plus with that $420 million war chest and the luxury of gaining so much experiential knowledge, I think they are in a healthy lead here.

Additive manufacturing seems to be a huge potential benefit for Adidas as they move into the next generation of footwear. In an industry that has seen (relatively) little innovation in recent years this feels like a breakthrough on par with Nike’s waffle outsole. I actually am not concerned about the price – if we have learned anything from Apple it is that people will pay extra for something that is “cutting edge” or “cool”. My concern lies with the quality. How will these 3D printed shoes hold up? Will they be comfortable to wear? Will they provide good traction, cushioning, etc.? It is possible that they will be able to deliver on all these things, but I would be concerned that in their rush to be first they forget about also trying to be the best quality, and do irreversible damage to the brand.

We did a Nike case, now I want an Adidas case too! This is a fascinating article, and like those who commented above, I had no idea of the extent 3D printing had extended into footwear. I can definitely see some uses for such customization outside of athletic apparel as well- consider that many blue-collar workers and military service members wear work boots almost every day. For them, the search for the right pair of boots is never-ending, and a good pair makes all the difference. I am surprised that this capability is not widely known, and wonder how they plan on marketing this to consumers in the near future. Great article!

I hadn’t thought of the military application. I know many big innovations have come through military development and adoption. I wholeheartedly agree that the military should test out 3D printed boots for soldiers that are on their feet all day. Obviously, questions of durability and reliability come to mind. But getting a military contract would add further credibility.

You mentioned that 3D printing of Adidas’ shoes will lead to a shorter product development cycle which will ultimately lead to faster product improvements. I am not particularly convinced at this point that the product development cycle will be significantly improved based on my elementary understanding of shoe manufacturing. I am working under the assumption that a very limited number of shoes are produced during the product development phase for testing purposes, which is why the total time spent for developing all “testing” shoes should not be that much longer without 3D printing. So, unless there is a significant set up time prior to manufacturing “testing” shoes, or that purchasing or creating of the equipment needed to manufacture such shoes require more time or effort, I am not sure if there will be an improvement in product development and improvement time/cycles.

From a customer standpoint, I do think that personalized shoes are huge. As someone who has had relatively flat feet and owns custom insoles since the age of 12, I can personally attest to the benefit of shoes that are customized and are actually “good” for your feet. As humans, we are on our feet for a significant amount of time every day and place enormous stress on them. Too often, we purchase shoes which look good but are actually terrible for our feet. I do hope that Adidas works with podiatrists to create personalized shoes through 3D printing which can actually benefit its customers (in addition to the performance or cool-factor).

Traditionally, one of the bottlenecks for developing new products is the tooling required to make a new pair of shoes. The molds required are both expensive and time-consuming. With 3D printing, a new pair could be made in the morning, tested in the afternoon, and reprinted with adjustments the following day. Currently, this is impossible. But once again, I think data collection is critical. Wouldn’t it be cool if you could show up to an Adidas store and they already know what your next pair should be based on data collected from your previous shoes?

To your second question, I think their ability to perform better than traditionally produced sportswear will depend on their ability to quickly incorporate multiple material types and generate sufficient demand. While it sounds like they have successfully expanded with new materials, they will likely need to push this further to offer the same product variety currently available in the highly competitive market for shoes. To really compete with traditional production, the new AM process needs to maintain product quality while introducing cost savings – cost savings alone likely won’t cut it. The product variety can also likely help increase demand for the new products. I agree with you that partnering with athletes will also lend credibility to this new line and increase demand. This seems a critical step to gaining traction with customers and closing in on their goal to sell 50 million pairs. While a fascinating and potentially lucrative endeavor, I think you’re right to approach the question of market demand, at least in the short term, with caution.

Very interesting to see a shoe manufacturer taking advantage of additive manufacturing! I think you bring up a very valid point in terms of the amount that consumers will be willing to pay for these new 3D printed shoes. I believe that in order for these types of manufactured shoes to be successful at that price point they will need to rely on credibility. This will likely need to come from a partnership with another prominent athlete, whether that be amongst the Company’s existing relationships or someone new. This would then provide the market with the signal that the shoes demonstrate equivalent or better performance capabilities than traditionally manufactured shoes, warranting their premium price point.

I love the idea of using additive manufacturing, not just to reduce production costs, but to empower personalization. Personally, I have difficulties buying shoes because I’m in-between two sizes and they don’t make half-sizes in my size; I would certainly pay a premium for on-demand shoes that would fit perfectly. I would also hope that, as the technology advances, it will eventually become cheaper and 3D-printed shoes could eventually be the norm. To answer your question, because shoes so rarely fit perfectly and because it is painful and potentially dangerous (i.e., injury-causing) to wear ill-fitting shoes, I do not think that additive manufacturing in shoes is a fad, especially if it addresses these issues.

True to our Nike case, I think marketing (celebrity/athlete endorsement) and product performance (with athlete input) would help this product sell despite the $400 price point. In addition, I can envision a gimmicky selection/creation process in real-time that might increase a customer’s willingness to pay. If I could walk into a store, get my foot scanned, and then select from 10 different models that are compatible with my foot type and the printer, and walk out with a high performance customized shoe 15 minutes later (after watching it get made), I would pay $400 (after my loans are gone).

What really excites me about this application of AM is how repeatable and repeated it is. With other applications (namely military or humanitarian), 3D printers would be asked to create many different products, and reconfigure between each print with potentially different raw materials. In this shoe context, much of the variability is removed, and Adidas can focus on improving reliability and efficiency while focusing on a single product. I wonder if the ways they address current AM reliability and efficiency issues will bleed over/be adopted by other industries and applications? Either way, this is very very interesting and I want a pair.

I wonder how Nike and the other competitors react to this innovation at Adidas. How is Adidas positioned differently than its competitors in terms of using 3D printing to produce shoes? Also, on the manufacturing side, I wondering if the 3D printing technology can significantly reduce costs in the long run. If so, then I see a big potential to scale up the number of 3D printed shoes. However, if such scaling efficiency cannot be achieved in the near term, then those shoes are likely remain a fad for die-hard sneaker fans.

On a separate note, if eventually 3D printing technology replaces a large portion of Adidas’ manufacturing, given that shoe manufacturing is still quite labor intensive, how will the company appropriately work with the manufacturing plant workers who will likely lose their jobs?

What a fascinating example. I am trying to imagine a world where a customer walks into a shoe store, is fitted, and has their shoes made for them while they wait. The ease with which 3D printing allows the construction of matrix structures and internal cavities suggests that additive manufactured shoes could have amazing ergonomic properties. I am curious to see how ADIDAS will turn 3D printing into a long-term competitive advantage that cannot just be copied by their competition. Partnerships with athletes will change drastically too. Product development teams will benefit greatly from decreased production times between iterations.

This is certainly a fascinating model of production for Adidas, which seems to have the potential to transform the entire sportswear and footwear industry. While the performance aspect may take time to prove out, there are huge potential improvements in the supply chain that can result in greater overall efficiency. Where this may be impactful is in the realm of sustainability. We saw that Nike used sustainability as a competitive advantage in our case on the World Cup – the Nike team found that sustainable products both served as a marketing tool and a product improvement point of differentiation. I wonder whether Adidas could leverage the benefits in carbon reduction (i.e. reduced transportation time/costs) as a point of differentiation that could increase sales.

To answer some of your questions, I don’t think the idea of 3D printed shoes is a fad. In fact, this makes sense as the next area of growth for a shoe company. Although using celebrities to promote a shoe brand is a popular idea now, one can assume that over time this strategy will become less effective. In a world where consumers can walk into a store, have their foot scanned, create a custom design, and walk out with a custom pair of shoes excitement around companies like Adidas will grow. This will be expensive at first, but like any technological innovation as adoption increases prices will move in the opposite direction.

To your second question – is this just a fad—I think that depends significantly on how much value consumers derive from personalized 3D printed shoes. Is it just a party trick or is it something that allows consumers to run faster and perform better? In my opinion, I think personalized 3D shoes feel like more of a niche item for elite runners and wealthy individuals, as it can’t be mass produced or fully commoditized. I thought it was interesting that you focused more on personalized consumer shoes, as opposed to using 3D printing in the manufacturing process. I worked on a consulting project for Nike and I was blown away by the significant difference in manufacturing steps across the large number of SKUs. This made creating a standardized process (and capital investments in machines) very difficult and is an area I could see 3D printing having a huge impact.

This is amazing! I did not know this was a thing in the shoe industry. Just imaging walking into the store, scanning my feet and walking out of the store with a custom made shoes sounds amazing. This could revolutionize the industry a 100%. My only concern is the impact in work in the future. How many employees will be fired in Adidas? How is the company thinking to do this shift from a more people intensive to capital intensive production?

I think this is not only a great example of additive manufacturing, but will also be a case that will lead into a distinctive use case of machine learning. The next logical step for Adidas would be to think about how it can best use the customer data it has collected to increase its revenue over time. For instance, if I had purchased my first pair of shoes, I provide Adidas not only my shoe size, but also my color preferences, shoelace preferences, etc., which Adidas can then analyze and use to send me digital e-mail pushes of similar products that others with my preferences had recently purchased.

Thus 3-D printing will unlock a new era for Adidas whereby they can have targeted advertising at an individual level. The revelation of individual preferences at unprecedented levels of granularity will provide Adidas a very large competitive advantage vs its peers.

This is a fantastic concept and I think this is how broader retail will be shaped in the future and the impact on store inventory cannot be understated. It eliminates waste almost entirely. Those who adapt last will be losers in the retail game; in-store 3D printing virtually eliminates out-of-stock issues. Retailers will also have less trouble predicting the upcoming trends and will be able to adjust the purchase of goods accordingly.

Really interesting read.

I believe technological breakthroughs are the #1 driver of product innovation at footwear companies such as Adidas & Nike. In the short-medium term, the most valuable benefits of these technological breakthroughs (such as 3D-printing) are the increased product customization & (eventually) reduced manufacturing costs. Adidas & Nike must now sprint to capture as much of this value via the first-mover advantage.

Long term however, the feasibility/sustainability of 3D-printed footwear will hinge entirely on product performance. If Adidas can not couple breakthroughs in 3D printing with advancements in product performance, the ultimate viability of 3D-printing/additive manufacturing will be at risk.

This was really exciting read especially because I wasn’t aware of the pace at which Adidas is ramping up the production of such shoes. Talking about 3D printing shoes makes me wonder the future of offline shopping experience. Today, the store experience is all about trying out different sizes of shoes and selecting basis how it looks and feels. I believe 3 D printing is pushing the offline experience more towards online and especially for a category like Fashion, I would doubt the scalability of this concept.

I’m a fan of Adidas shoes and was very excited when the Futurecraft 4D dropped! Although revolutionary today, the cost of technology usually drops with quick industry adoption and I wouldn’t be surprised if the shoes are much more affordable in the near future. In order to successfully sell massive volumes, 3D printed shoes can utilize the following strategies to sell even at high price points:

1) There is a market for custom shoes particularly for those people who’s feet are in between sizes or require additional support features. Lots of medical applications on this front.

2) There is a large market in the sneakerhead community for customizable design shoes.

Shortening the product innovation cycle inevitably also shortens the product fashion cycle, so I suspect this adds pressure on Adidas to release more and more sneaker innovations (on top of their already dizzying number of colorways).

Very interesting read – also just read another essay about Nike’s use of 3D printing. Would echo comments above that it would be interesting to see who wins in this space and what the broader competitive landscape is. How are the cost structures going to change in the future? What is the demand for this kind of product in the broader consumer segment vs the star athlete segment?

I’d love to better understand the economics of Adidas’s 3D printed shoes. Adidas could either focus on improving performance, or on lowering costs of its shoes. It seems likely that in the beginning, Adidas would have to focus more on performance (and selling to extreme users / early adopters), and then reduce costs over time to serve a broader market for the product. I expect that the key to encouraging broader adoption of 3D printed shoes will be to convince KOLs like athletes and celebrities of the value of the shoes from a functional/performance perspective. However, to the extent that the market for high-end shoes is a “luxury” market that values scarcity and exclusivity, it might be hard to convince customers that a shoe that is printed can be exclusive.

Great essay! I think 3D printing in sneakers is a really interesting application of the technology. My main concerns would be 1) in a time where people are increasingly making purchases online, how will the foot scanning process work so that you can still get a shoe that’s custom-fit to your foot? 2) the price. I don’t think that 3D-printed shoes will have mass appeal at the $400 price tag. That being said, I’m sure that the production cost will come down over time and Adidas will be able to pass that through to the customer with more reasonable prices. The question is when do we think that will happen?

One question I had is about the Speedfactories and if this applies to 3D printing of midsoles or the production of other parts of the shoe. Because if its the latter, then the 3D printing production process will still need to catch up in terms of time and cost to match the effectiveness of the new Speedfactories. Are there a lot of Carbon 3D printers at these Speedfactories. I would love to learn more about the actual economics of using Carbon 3D printers vs. traditional production processes.

Shoe production contains two main components: the midsole (which I focus on here) and the upper. To date, the Speedfactories have primarily focused on the uppers of the shoes, using new machine knitting technology, but with a strong focus on speed and variation. To be honest, I’m not convinced that 3D printing will ever be at a lower cost than traditional manufacturing, where materials are molded into the desired shapes are very large volumes. Also, remember that Carbon needs to make money on every 3D printed shoe as well.

As implied in the article, the real question is demand. If the shoe is materially better at being a shoe, are consumers willing to pay? Historically, Nike and Adidas have done a great job of creating demand… where’s the limit?

Great read.

I have no doubt in my mind that Adidas will provide truly superior performance with 3D printed footwear over traditional athletic footwear. However, my biggest reservation is less about the technology and more about distribution. With a push towards online retail, I think apart from your elite athletes that would come into a store to get shoes made, a lot of others may resort to a flexible shoe model that contorts to your foot type, rather than relying on physical irregularities (unique to each persons foot) that needs to be capture in the 3D printing process. Companies are doing this in the clothing space [1] – while seemingly low tech, its also a lot more scalable (its able to manufacture at a one-size fits all approach, but provide a custom experience because of materials selection). Curious to see how 3D printing can address these issues – and if it is truly a fad, or can it maintain a niche target market for the elite athletes of the world.

[1] https://www.mizzenandmain.com/

Wouldn’t it be cool if your sneakers could be on a subscription model!? They put sensors in your shoes and analyze the performance for a year. Every year, Adidas sends you a new pair with all the improvements you need based on your last pair of customized shoes. That’s the future of online retail! Customization, curation, personalization, convenience, etc. All with predictive demand!

Great use case for additive manufacturing – performance shoes are well-suited for 3D printing given the demand for highly customized shoes to fit individual shapes. As a runner, I would be very interested in getting a pair of shoes in 15 minutes that is specifically designed for my feet and would probably be willing to pay a high price (in the long term certainly the cost will go down so I would not be too concerned with the initial high price tag). I would expect many other consumer and more specifically apparel brands to also follow suit and adopt 3D printing in their production processes. It is fascinating to see the evolution of moving from small batch, localized production to industrial assembly lines and finally back again to customized local production.

I’m not totally convinced that personalized 3D printed shoes are far better quality than currently available sizes for the vast majority of people and that people would be willing to pay incrementally more for this. Custom shoes likely fills a niche for consumers with unique foot shapes and sizes, though with the glut of shoe and insole options currently available, it’s hard to see that there is a large segment that is grossly underserved today. Several shoes already form to a person’s foot over time and mold to a personalized fit, like wool Allbirds or supple leather oxfords. In that respect, it’s difficult to see that a 3D printed shoe would be able to command a price premium. Athletic shoes may be different as they might be made out of more rigid upper materials. However, are producing finer size increments, such as quarter sizes, a more economical solution? It seems from previous comments that 3D printing may simply always have a higher cost basis than traditional mold-injected manufacturing at scale, so the benefits to a 3D printed shoe may simply be the novelty of a custom product. The real value to consumers may be the instantaneous nature of the product, allowing consumers anywhere, in cities large or small, to choose from the entire global assortment of products. Further, stores could carry far less inventory and save significantly on these carrying costs. It’s unclear if these savings outweigh the costs of higher per-unit production.

Very cool post! I love adidas, and I’m very excited about the new design possibilities 3-D printing will bring. I think what will truly propel this idea are aesthetics and cost. The shoes appear unlike anything else people are wearing. From a cost standpoint, companies such as Adidas may be able to cut China out from producing our goods.

Great post. It’s very interesting that 3-D printing can have such a meaningful impact on their supply chain. It seems in line with the market trends of personalization and supporting local. If they can successfully implement consistently, this could really inspire other companies to jump on the bandwagon of 3-D printing, which will be when things really start to change.