ADIDAS – Additive Manufacturing for the Masses

Adidas has entered the world of additive manufacturing through the introduction of its Futurecraft 4D shoe. With mass customization using 3D printing as the ultimate goal, questions remain whether Adidas will be the first athletic retail company to affordably scale the technology.

A NEW ARENA FOR ADDITIVE MANUFACTURING

Plane components, automobile parts, building materials…running shoes?

Recent advances in the speed, flexibility, and cost of additive manufacturing (AM) have made it accessible to industries previously concerned about the technology’s scalability [1]. One such industry is retail, where firms are increasingly looking to 3D printing to quickly and affordably provide customers with customized products.

Adidas is leading the way for retailors with the launch of its first commercially-viable 3D-printed shoe in 2017 and goal to use 3D printing for mass production in the future [2]. Driving the company’s adoption of AM is its “Creating the New” strategy, which includes goals to dramatically expand product customization options while reducing production lead times [3]. Key competitors Nike and Under Armour are putting additional pressure on Adidas by exploring the use of AM in their own product development process, but mostly in the form of prototypes or rare limited additions [4]. If successful, Adidas’ ability to affordably scale AM will be a key competitive advantage in the years to come.

3D PRINTING FOR 4D SHOES

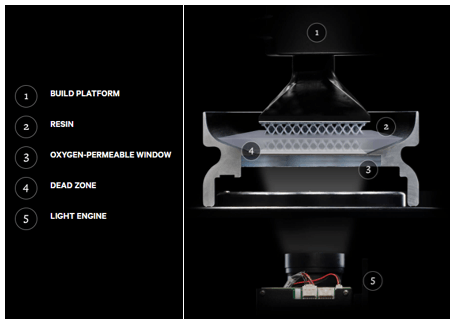

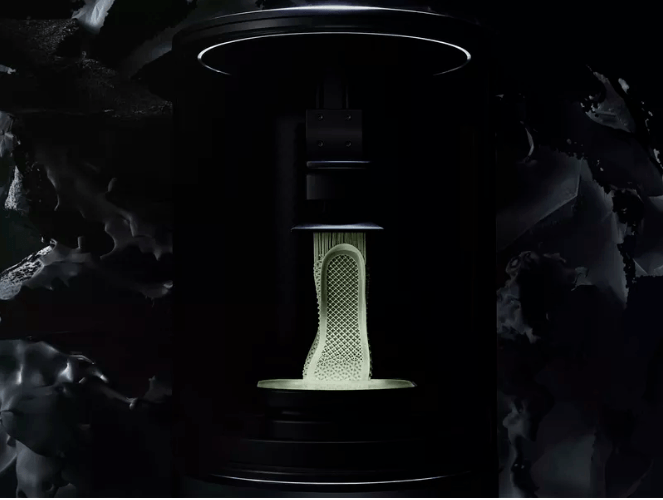

The Futurecraft isn’t Adidas’ first foray into 3D printing; the company has used the technology to test prototypes in the past, and even did a limited release of a 3D-printed running shoe in 2015 [7]. What’s different this time is the fact that CLIP’s use of production-grade materials and its ability to vary firmness across the sole structure now make it possible to produce final products through AM [8]. Adidas’ short-term goals are to produce 100,000 pairs of the Futurecraft 4D shoes in 2018, and to ramp up production to the millions in the coming years [9]. The shoe’s current price tag is $300, but James Carnes, VP of strategy creation for Adidas, reports that the shoe price may be cut down once a certain volume is reached [10].

CONSIDERATIONS FOR GROWTH

As Adidas looks to scale custom production in the long term, there are a number of actions it should take to enhance the customer experience while controlling costs. Installing 3D printers in stores would allow for immediate customization and give customers a cool experience, while also reducing waste and eliminate out-of-stock issues. Boston-based fashion retailer Ministry of Supply is one company doing this well today; they have a 3D printing machine in store that can make a custom garment on demand in one-and-a-half hours [17]. Additionally, curating “recommended configurations” for shoes and postponing customization to the last point possible will hopefully help Adidas manage the infinite variability that comes from mass customization [18].

WHAT’S NEXT?

The Futurecraft 4Ds are a strong starting point for Adidas in the 3D printing space, but success is not guaranteed. Two key questions the company will have to grapple with as it attempts to affordably scale the technology for mass customization:

- How will functions outside of R&D and production need to evolve to support the integration of 3D-printed products into Adidas’ product portfolio (e.g. sales, supply chain)?

- Will Adidas be able to bring down the $300 price tag of the Futurecraft 4Ds so that the product is affordable for a wider customer base? What steps will it need to take to achieve this goal? (765 words)

[Cover photo] Wilson, Mark. “How Adidas Cracked The Code Of 3D-Printed Shoes.” Fast Company. July 09, 2018. Accessed November 2018. https://www.fastcompany.com/90138066/how-adidas-cracked-the-code-of-3-d-printed-shoes.

[1] D’Aveni, Richard A. 2018. “The 3-D Printing Playbook.” Harvard Business Review 96 (4): 106–13. http://ezpprod1.hul.harvard.edu/login?url=http://search.ebscohost.com/login.aspx?direct=true&db=bth&AN=130332120&site=ehost-live&scope=site.

[2] Adidas, 2017 Annual Report, p. 64-75 https://report.adidasgroup.com/media/pdf/EN/adidas_AR_2017_EN.pdf, accessed November 2018

[3] Wilson, Mark. “How Adidas Cracked The Code Of 3D-Printed Shoes.” Fast Company. July 09, 2018. Accessed November 2018. https://www.fastcompany.com/90138066/how-adidas-cracked-the-code-of-3-d-printed-shoes.

[4] Strategy, from Adidas website, https://www.adidas-group.com/en/group/strategy-overview/

[5] Adidas, 2017 Annual Report, p. 64-75

[6] The perfect fit: Carbon + Adidas collaborate to upend athletic footwear, from Carbon website, https://www.carbon3d.com/stories/adidas/

[7] “Adidas makes first 3D shoe available for purchase with exclusive drop,” press release, December 12, 2016, on Adidas website, https://news.adidas.com/us/Latest-News/adidas-makes-first-3d-shoe-available-for-purchase-with-exclusive-drop/s/7004e8fa-324b-4b71-bc2f-aacf3d61b135, accessed Nov 2018

[8] The perfect fit: Carbon + Adidas collaborate to upend athletic footwear, from Carbon website

[9] Cheng, Andria. “How Adidas Plans To Bring 3D Printing To The Masses.” Forbes. May 23, 2018. Accessed November 2018. https://www.forbes.com/sites/andriacheng/2018/05/22/with-adidas-3d-printing-may-finally-see-its-mass-retail-potential/#2a411b8a4a60.

[10] Ibid

[11] Ibid

[12] Ibid

[13] The perfect fit: Carbon + Adidas collaborate to upend athletic footwear, from Carbon website

[14] Futurecraft 4D Controlled Energy, from Adidas website, https://www.adidas.com/us/futurecraft

[15] Horaczek, Stan. “Nike Hacked a 3D Printer to Make Its New Shoe for Elite Marathon Runners.” Popular Science. April 17, 2018. Accessed November 2018. https://www.popsci.com/nike-3d-printed-sneakers.

[16] “Appalatch Wants to 3D Print Your Next Sweater.” Wired. August 07, 2015. Accessed November 2018. https://www.wired.com/wiredinsider/2013/11/appalatch-wants-to-3d-print-your-next-sweater/.

[17] Kestenbaum, Richard. “3D Printing In-Store Is Very Close And Retailers Need To Address It.” Forbes. April 06, 2017. Accessed November 13, 2018. https://www.forbes.com/sites/richardkestenbaum/2017/04/06/3d-printing-in-store-is-very-close-and-retailers-need-to-address-it/#3c81b69c33b4.

[18] Gandhi, Anshuk, Carmen Magar, and Roger Roberts. “How Technology Can Drive the next Wave of Mass Customization.” McKinsey. Accessed November 2018. https://www.mckinsey.com/~/media/mckinsey/dotcom/client_service/bto/pdf/mobt32_02-09_masscustom_r4.ashx.

[19] Futurecraft 4D Controlled Energy, from Adidas website

From a marketing perspective, this application of additive manufacturing is quite sexy! If I were to be optimistic and assume that the technology will be scalable and cheap enough to install in every Adidas retail shop, my follow-on question would be – what is the customer value? Customized orthotics in shoes are invaluable for correcting postural and gait issues, but their design requires complex tests by a podiatrist. If the customization, therefore, were purely aesthetic, why do this “on the spot” over the existing model of ordering customized shoes online that can be manufactured in factory for cheaper?

In response to Jeff above, Nike had a successful campaign in the early 2000’s of letting customers “customize” (rudimentary changes in color and ankle protection) their basketball shoes online — I suspect the customization component would resonate with young customers. However, I do question the customers’ ability to create a functionally sound shoe if given too much leeway in design decisions. And if the level of customization is limited, what will be their appetite to pay a premium for the product?

Really interesting article — you point out great benefits 3D printing has begun to offer Adidas, and I agree with all your recommendations. It’s interesting to compare Adidas’s product strategy with that of competitor Nike. Given that Nike has historically created products by partnering with powerhouse athletes to iterate and improve upon them, I wonder how customers might respond to Adidas’ “democratization” of product design and iteration through 3D printing. Putting 3D printers in Adidas stores would put customers in the drivers seat; but will this impact Adidas’ brand as a whole? In a world where consumers can walk into a store and design/print their own shoe, does the Adidas brand slowly lose its “stamp of approval” of a shoe crafted by experts? or rather, will consumers embrace this newfound agency in the shoe purchase journey?

Do you think Adidas will find a way to reduce production costs? AM seems to be low in fixed costs but very high in variable costs, especially the cost of the raw materials. Raw material prices seem to be outside of the company’s control — what other ways could they reduce costs to the point that shoes made with this technology rival the prices of shoes of similar quality?

Also, Adidas seems to be missing a major opportunity here. As you mention, they’re focused on standard shoe sizes. Why not go with people with big feet? The selection for shoes over size 13-14 (US) is extraordinarily limited.

Thanks for sharing the article! It is very interesting. I didn’t know that there have been very practical applications of additive manufacturing as in the case of the Ministry of Supply. To answer your question whether Adidas will be able to bring down the cost of the 3D-printed products, I think that this will largely be dependent on the progress of the 3D technology, which is still in a very early stage. Other tech companies, not Adidas, are developing the technology, so if Adidas truly believes that the customization through 3D can become one of its core competitive advantages, it doesn’t seem farfetched to suggest investing in one of those tech companies to have the proprietary technology. In fact, many companies (outside of tech) have their own venture/incubator fund to invest in small but promising emerging tech companies!

If Adidas moves towards more 3D printing, I wonder about the eventual role of other groups within the company. If 3D printing comes front and center, then those with specialized roles in dealing with manufacturing and sourcing will have to pivot towards items used in making 3D printing. Someone whose role is to source the rubber soles of sneakers might not have a job or function anymore in the company because now you need someone who sources the “ink” that goes into the 3D printer. We should consider the impact on the organization from such a change and the transition time that this will require.