3D Printing…we should ‘Just Do It’!

Feet wide apart, arms down by his side, he stares at the precise location where he will place the ball with his right foot. Before the run-up, there is an empathic sigh, with his lips pursed, as his shoulders go up and down, almost in emphatic fashion. [1] Cristiano Ronaldo runs up, strikes the center of the ball with his new Nike Mercurial Superfly CR7 boots, and sees the ball whiz past the goalkeeper, into the back of the net.

As CR7 sprints in elation towards the corner flag to celebrate the goal with fans and fellow teammates, a more modest celebration is taking place in Beaverton, Oregon – home to Nike Inc.’s global headquarters and base for the Nike Football development team. For several months, their team went through numerous iterations of design development, product testing and finally commercialization to get their newest product into the hands (or rather, feet) of one of the sports’ greatest football (i.e. soccer) icons.

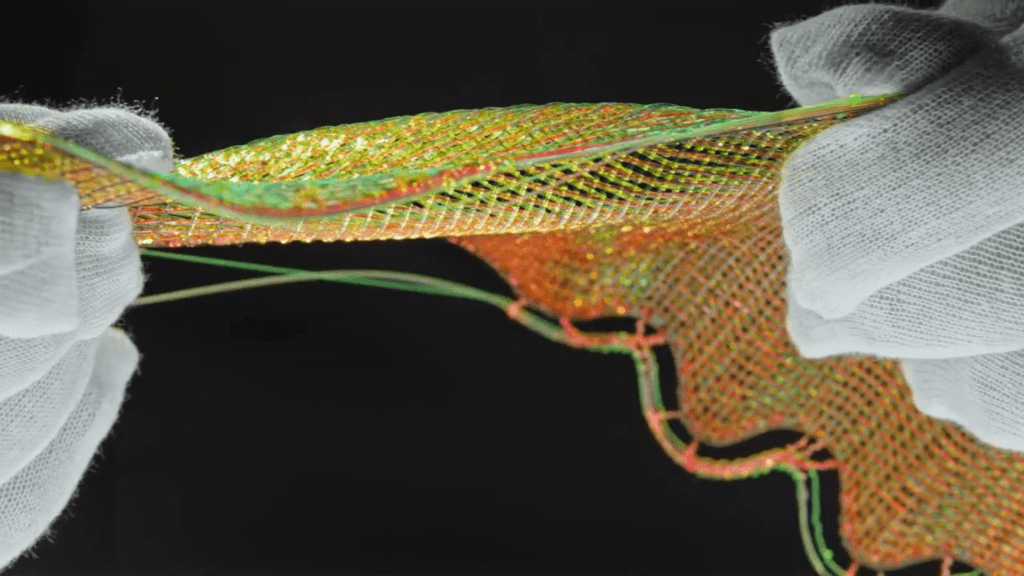

[2] For the latest edition of the Mercurial football boot, Nike identified ‘fit’ as the focal point for their new product design. The boots’ game-changing 360 construction was only made possible through a new advancement in Nike Flyknit technology. [3] This technology has allowed Nike to establish yarns and fabric variations that are precisely engineered to create the lightest-possible, form-fitting and virtually seamless upper (i.e. the part of the shoe that covers the top/sides of foot and the back of the heel). [4]

[2] For the latest edition of the Mercurial football boot, Nike identified ‘fit’ as the focal point for their new product design. The boots’ game-changing 360 construction was only made possible through a new advancement in Nike Flyknit technology. [3] This technology has allowed Nike to establish yarns and fabric variations that are precisely engineered to create the lightest-possible, form-fitting and virtually seamless upper (i.e. the part of the shoe that covers the top/sides of foot and the back of the heel). [4]

Introducing Nike Flyprint [2]

But as Nike continues to lead the charge in product development for new football footwear, it is faced with two key challenges: lengthy product development timelines and increased demand for product customization. From the first sketch of a completely new pair of boots, to making and testing prototypes, ordering materials, sending samples back and forth, retooling a factory, working up production and eventually shipping the finished goods to the shops can take the company as long as 18 months. Yet, market demand for a boot may only last the length of a football season – ten months. [5] Additionally, athletes are finding the need for extreme customization to best address their athletic needs to provide a competitive advantage.

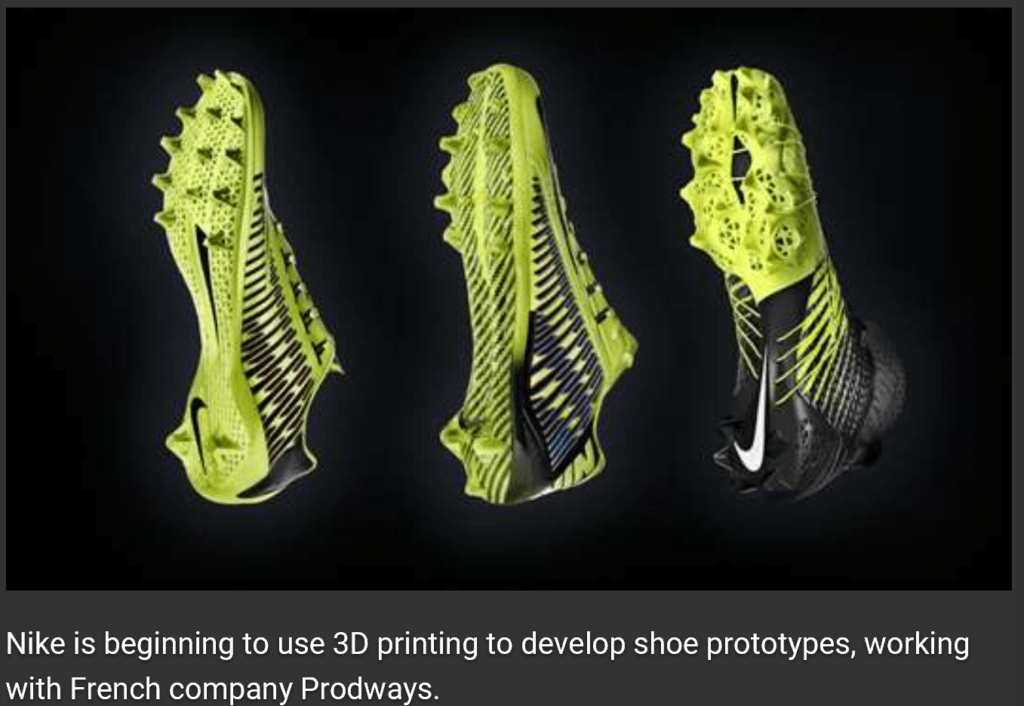

[6] This is where Nike is actively exploring advanced manufacturing technologies to further elevate the value of their product offerings. Nike’s recent partnership with Prodways, a global provider of industrial 3D printers, has allowed them to 3D-print outsoles, midsoles and insoles which are made from thermoplastic polyurethane (TPU) material. The TPU material allows Nike to decrease manufacturing time while also providing higher performance and customization for top athletes. [6]

[6] This is where Nike is actively exploring advanced manufacturing technologies to further elevate the value of their product offerings. Nike’s recent partnership with Prodways, a global provider of industrial 3D printers, has allowed them to 3D-print outsoles, midsoles and insoles which are made from thermoplastic polyurethane (TPU) material. The TPU material allows Nike to decrease manufacturing time while also providing higher performance and customization for top athletes. [6]

Although the prospects for additive manufacturing at Nike are bright, 3D-printing is not ubiquitous yet. Generally, it is too slow for mass production, too expensive for some applications and for others it results in products that are not up to the desired standard. [7] Advancements in additive manufacturing will surely help mitigate current challenges with speed and cost, but what Nike must make sure it protects is product performance.

So much of Nike’s established success has been lifted by the remarkable success of endorsement deals with elite athletes. Over the years, these athletes have proudly worn Nike gear/boots because of their innovative and cutting-edge aesthetics, but more importantly, their top performance. Even Cristiano Ronaldo attests that the latest Nike Mercurial Superfly CR7 boots are a supreme product. “They fit perfectly. The 360 innovation — it is perfect. They are comfortable and they look good, so they have everything.” [3] As Nike looks to incorporate 3D printing technologies into their global manufacturing strategy, they need to ensure their products remain ‘perfect’ for athletes, so they can be their ‘everything’.

Nike is not the only player actively exploring opportunities in additive manufacturing and 3D-printing. In summer of 2017, Adidas began manufacturing at a new production facility in Ansbach, Germany – poised to use robots and novel production techniques (such as 3D printing) to also shorten supply lead times and boost their product customization. Nike turned the football tide (away from Adidas) between the 1980’s and early 2000’s through innovative product development and effective digital marketing. Could an Adidas ‘win’ in additive manufacturing/3D printing reverse the football product tide back in their favor?

(700 words)

[1] Talbot, J. (2018, June 30). The Reason Why Cristiano Ronaldo Does His Trademark Stance Before Taking Free-Kicks. Retrieved from http://www.sportbible.com/football/football-news-the-reason-why-ronaldo-does-trademark-stance-before-free-kicks-20180630

[2] NIKE News. (2018, February 07). Introducing the Mercurial Superfly and Vapor 360: Fast By Nature. Retrieved from https://news.nike.com/news/mercurial-superfly-vapor-360

[3] NIKE News. (2012, February 21). NIKE engineers knit for performance. Retrieved from https://news.nike.com/news/nike-flyknit

[4] NIKE. Introducing Nike Flyprint. (2018, April 13). Retrieved from https://youtu.be/RFW35vTTGQI

[5] Adidas’s high-tech factory brings production back to Germany. (2017, January 14). The Economist.com. Retrieved from https://www.economist.com/business/2017/01/14/adidass-high-tech-factory-brings-production-back-to-germany

[6] Caliendo, H. (2018, January 5). 3D-Printed Sneakers Gaining Traction. Retrieved from https://www.additivemanufacturing.media/blog/post/3d-printed-sneakers-gaining-traction(2)

[7] 3D-Printed Sneakers Gaining Traction. (2017, June 29). The Economist.com. Retrieved from https://www.economist.com/briefing/2017/06/29/3d-printers-start-to-build-factories-of-the-future?zid=293&ah=e50f636873b42369614615ba3c16df4a

This reflection on the future viability of 3D printing for Nike touches on the key balance between R&D time and performance. I would wonder how the thermoplastic polyurethane material, though surely with manufacturing time benefits, performs relative to Nike’s other materials. Nike has generally not shied away from longer product development times given their central focus on providing their elite athletes with the best possible product. If there is a performance gap between the TPU and other materials, it should be interesting to see how Nike treats this trade off in the medium term while further investment in the technology progressively shrinks the gap.

I really enjoyed this post. One item that your essay touches on that I think is critical is the quality factor of the 3D printing. Nike has focused so much on their R&D and performance that it is absolutely necessary that these 3D printed shoes maintain this same level of quality – which it seems to be doing so far. To answer your question on whether Adidas could turn the tide, I think they could potentially have the opportunity if they could allow for optimal customization at a price and timing that works for the consumer – but sounds like we are still some time away from this type of customization, speed and cost combination.

Wonderfully written! Thanks for an extremely interesting post that shed light on a 3D printed product from the perspective of the consumer.

Similar to the trade-off between sustainable kits and performance, I have found myself wondering (perhaps naively) if 3D printed shoes could really lend themselves to the demands of a football game. I suspect that Nike, along with other athletic shoe giants, may have to spend time educating the mass market as to how 3D printing capabilities have progressed since the mainstream media first introduced the concept. When I think 3D printing, I still think rigid. Nevertheless, if they are good enough for CR7, they’re probably good enough for us all!

Very interesting information on the prospect of 3D printing for Nike! In terms of maintaining a competitive advantage over Adidas, I do feel that Nike must maintain an edge in this 3D printing movement to do so. As Nike has established itself as an innovator in the space, in order to keep that image amongst its consumer base it needs to focus on staying at the forefront of its production processes. As a result, since Adidas has made a conscious effort to commit resources to additive manufacturing it will be crucial that Nike do the same in order to sustain a competitive advantage.

This is a very interesting article, especially in light of the recent Nike case in marketing! My main question: Does the consumer really care how its shoes are produced or is it more of a gimmick? As a consumer, my only concern would revolve around quality control – just make sure my shoes are as functional / comfortable as non-3D-printed shoes. The obvious benefit is to the manufacturer. R&D becomes more powerful, making innovation more attainable, and mass production allows for major cost synergies – and would also allow Nike to further distance itself from suspicious employment practices.

Great article!

3D printing can open true innovation for customization! In addition, I think, Nike can reduce inventory and logistics costs by applying Just In Time production. My question would be: As 3D printing becomes advanced and prevalent, is it possible some random small manufacturer just produce Nike’s products with 3D printers? What if Nike’s 3D design and drawing, somehow, are exposed to the public and people can just produce without permission or paying anything to Nike? What would be the meaning of being a manufacturer in that world?

This is a very informative article that highlights the game-changing potential of 3D printing when it comes to innovation and customization in manufactured goods. My key concern with Nike’s use of 3D technology in its R&D process has to do with the scalability of the approach given current constraints with the technology relating to speed and at times unfeasible costs. For now, this continues to be an interesting conceptual application of 3D technology, yet it remains to be seen whether Nike will be able to elevate its use to the level of scale where its beneficial impacts are felt across the spectrum of Nike’s value chain.

Learning about Nike’s entry into additive manufacturing / 3D printing leaves me wondering whether 3D printing will provide a meaningful improvement to Nike’s product development and process, or whether it is more of a marketing/PR strategy playing off the trendy nature of 3D printing. It is early days for 3D printing in the shoe space, and I am unsure if 3D printing will enable a shoe manufacturer to improve its product development innovation or process to the extent required to gain a competitive edge (i.e., for Adidas to overtake Nike). As posts above have described, Nike’s longer product development cycle may be necessary to sustain the quality and innovation that the brand is known for (e.g., through using their athletes to test/iterate on the product design), and I am skeptical that 3D printing will provide a meaningful benefit in this realm. In terms of process improvement and cost/logistics/timing efficiencies, more time and experience integrating 3D printing into the process will be required to draw any conclusions.

I wonder why Nike decided to pilot 3D printed shoes in soccer boots first instead of other sports shoes or casual wear shoes. Also, it is very consistent with Nike’s past strategy to test out new products with extreme users, i.e. the pro athletes. However, if Nike’s goal is to use 3D printing technology in mass production, and there are many hurdles to such scaling up process at the moment, I wonder if it makes more sense to test the products on ordinary people, the majority consumers, to figure out how to change the products to overcome the scalability challenges.

Great article! To me, the competitive advantage of 3D printing in the short term is less about mass production and more about rapid prototyping, and therefore faster innovation timelines, which is something Nike has been known for. However, a big question I have is what will happen if consumer preferences shift? For example, there is a large trend now towards athleisure, something that Adidas has capitalized on quite well, while Nike has not. I wonder if 3D printing provides any type of advantage in this scenario. In my opinion, it does, but requires Nike to shift overall strategy first, rather than just hoping 3D printing will be the competitive advantage rather than a means to deliver against a strategy.

It was fascinating to learn how Nike is leveraging 3-D printing to create customized cleats for professional footballers. I would imagine it allows for rapid prototyping for new designs and client needs. And if Nike is able to cut down the R&D and supply chain lead time, this could make mass production viable. You bring up several legitimate concerns to which I would add a couple more. From my understanding of 3-D printing, a significant concern among industry experts is durability of the building material compared to that of traditional shoe manufacturing. I am also curious to know how this technology impacts the company’s pricing strategy. Should the company achieve scale, would Nike lower the pricing of cleats? Or would it be cause for an additional premium? I am not sure how Nike would go about it, but I think it is innovative to incorporate 3-D printing in the product development process.

What a fun article to read! Love your writing style in the first bit. In the final question that you pose, you bring up the concern of how such technology advancements can lead to dramatic changes in competitive landscapes. I think it is a legitimate concern — if Adidas or another reputable player in the space makes the necessary technological advancements in 3D printing more quickly, Nike’s top position in the football cleat market could be at risk and share could dissipate quickly. This is the constant struggle that players face in highly competitive markets when it comes to product innovation, especially in industries with low switching costs. Such companies must always be innovating to consistently launch new product innovation. As such, a key question remains: do you (A) come to market with a subpar product from a technical perspective in order to get the first mover advantage with the new technology and reputation for innovation and risk customers being disappointed by product quality, or do you (B) wait until you have the new innovation “perfected” to a point where its product quality exceeds the legacy products? Further, when the product is not yet at optimal quality, do you price it above or below the higher quality legacy products despite the new innovation or do you price it for the future?

Terrific post! 3D printing brings a whole new dimension to retail. Given the ability to mass customize, I wonder if Nike should first experiment with using their 3D-printed products on the mass general population rather than using their typical R&D process of utilizing elite athletes. This may be more effective because more time and experience integrating 3D printing into the process will be required to draw any conclusions.

Goooooaaaallllllllll! You definitely scored with this one. While I agree Nike’s use of 3D printing is important to maintaining its edge as the perceived leader in technological innovation (e.g., R&D lab), I don’t think 3D printing has the potential to save the Company Cost of Goods Sold at scale. The customization and advanced engineering that AM fulfills is just not present at Nike. Moreover, I believe that Nike’s market positioning / brand equity is so well entrenched with their target market that Adidas will not be able to out-class Nike simply because of a foray into 3D printing.

Perfect timing with our Nike case! You mentioned that 3D printing hasn’t scaled in this industry due to its long cycle time and high cost. While we wait for the mechanics of 3D printing to improve over time, I wonder if Nike could use the current technology to tap into an ultra-high-end market with customized shoes. Cycle time and cost would be less important in this segment, and they could become early adopters, potentially giving Nike a competitive edge in the future by cementing its brand as a leader in 3D printed shoes before Adidas launches its own 3D printed products.

Awesome essay! Very interested in reading more about Nike’s use of 3D printing. Also agree with Mandy above, I’m interested in learning more about why this product was rolled out first for higher profile users vs the mass audience. Wondering if it was to maintain their dominant position against Adidas.

I wonder if the additive manufacturing / 3D for sneakers is actually something that is driving demand. Besides the technological advancements, I wonder if it will be sold and mass produced at a price point that will make sense to consumers. An example of this would be the ski boots we read about in our marketing product introduction case. Just because a product has excellent technology doesn’t mean that it can make commercial sense from a price and customer need standpoint. This begs the question whether a “win” for Adidas in 3D printing will actually help the football product tide since I’m not sure if it will drive the right type of customer demand.

Very interesting post on one of my favorite companies! I love what 3D printing will do for sneaker customization, and I believe consumers will too. It will be interesting to see if Nike or Adidas will master this manufacturing first.

Interesting article. Strongly agree with the sentiment that Nike needs to keep their focus on the performance of their shoes that get to market. For that reason, the quality of manufacturing that comes from the 3D process is the number one qualifier for me. That said, given the ability for 3D printing to manufacture many dynamic designs in a short period of time, I’m less concerned with a given 3D prototype design’s impact on performance while they’re building out the tech. From the perspective of Nike’s long term R&D team, if they can get high quality 3D shoe manufacturing ready for market, then I think their product design team can do the rest.

I wonder whether the industry and Nike is ready to widely commercialize a shoe built with 3D printed components just yet? As the article highlights, there are significant implications on Nike’s ability to deliver, specifically with the increased production lead time. While the product undoubtedly seems superior, could a strong but premature focus on 3D printed shoes serve as a distraction from their core business?